upload photo | donate | calendar

|

my profile |

register |

faq |

search upload photo | donate | calendar |

|

|

#1 |

|

User

Join Date: Jul 2004

Location: Europe

Posts: 112

Thanks: 0

Thanked 2 Times in 2 Posts

|

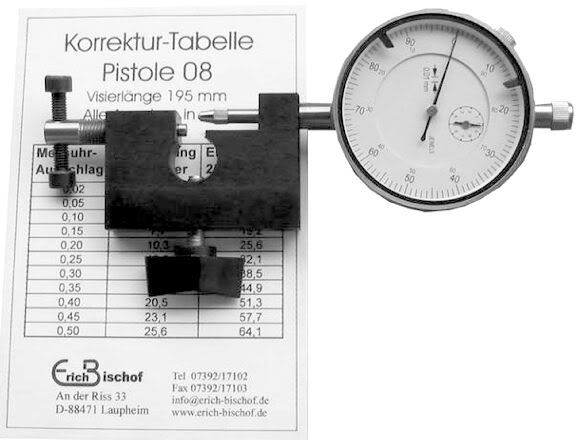

Noticed this one at the site of a German manufacturer (the link is with the picture). Its a very precise sight wrench for the 9mm Lugers (so not the .30 Swiss ones) and the price in Europe is 72,= ($ 89.=)euro which I find very fair ! The card that goes with it lists the amount of movement needed to correct the sight blade at several shooting distances and the micrometer allows you to work very precise. Thanks, Guisan.

__________________

Fight to your last cartridge, then fight with your bayonets. No surrender. Fight to the death. --Gen. Henri Guisan, Switzerland, July '40 |

|

|

|

|

|

#2 |

|

User

Join Date: Jun 2002

Location: Texas

Posts: 1,016

Thanks: 94

Thanked 275 Times in 137 Posts

|

Looks nice but that set-screw will probably marr the barrel.

SteveM |

|

|

|

|

|

#3 |

|

User

Join Date: Jul 2004

Location: Europe

Posts: 112

Thanks: 0

Thanked 2 Times in 2 Posts

|

Yep that's what I thought too but it should not be difficult to make a solution for that.

Thanks, Guisan.

__________________

Fight to your last cartridge, then fight with your bayonets. No surrender. Fight to the death. --Gen. Henri Guisan, Switzerland, July '40 |

|

|

|

|

|

#4 |

|

Administrator

& Site Owner LugerForum Patron Join Date: Jun 2002

Location: A Little NE of Somewhere...

Posts: 2,651

Thanks: 478

Thanked 517 Times in 129 Posts

|

</font><blockquote><font size="1" face="Verdana,Tahoma,Arial,Helvetica,Geneva">quote:</font><hr /><font size="2" face="Verdana,Tahoma,Arial,Helvetica,Geneva">Originally posted by Guisan:

<strong>Yep that's what I thought too but it should not be difficult to make a solution for that.....</strong></font><hr /></blockquote><font size="2" face="Verdana,Tahoma,Arial,Helvetica,Geneva">Hi Guisan, I think you are right. If you put a small square of rubber - like a square from a bicycle "inner tube" over that screw - it should be fine.... Very nice! Thanks! John D. |

|

|

|

|

|

#5 |

|

RIP

Patron LugerForum Patron Join Date: Jun 2002

Location: Hot & Dry PHX, AZ

Posts: 2,078

Thanks: 24

Thanked 164 Times in 87 Posts

|

I really hope that GT will chime in on this one. He has a front sight adjusting tool that has a tip that doesn't rotate with the adjustment screw. I believe that there is a small ball joint between the tip and screw. There is enough friction between the sight and tip to hold it from rotating. It's a great design!

|

|

|

|

|

|

#6 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: Chandler Arizona

Posts: 3,540

Thanks: 1,342

Thanked 3,735 Times in 1,019 Posts

|

Hi Frank, & all! Frank, you are correct in that the tool will most likely scrub on the sight itself, and the set screw is a definite NO!!!.... but, the dial indicator is quite clever!! although a bit of overkill in my estimation... Some of the Swiss type, which is what I think mine is, has a hardened steel anvil, that the tip of the threaded part impinges on, for the lateral movement of the sight... so it dosen't scrub on the finish... still all in all, a pretty good deal for the shooter, for the price... Best to all! til..lat'r...GT <img border="0" alt="[jumper]" title="" src="graemlins/jumper.gif" /> <img border="0" alt="[jumper]" title="" src="graemlins/jumper.gif" />

|

|

|

|

|

|

#7 |

|

Administrator

& Site Owner LugerForum Patron Join Date: Jun 2002

Location: A Little NE of Somewhere...

Posts: 2,651

Thanks: 478

Thanked 517 Times in 129 Posts

|

Well.......

Here is a silly question (I guess the rubber suggestion is out-the-window.... <img border="0" title="" alt="[Wink]" src="wink.gif" /> ) Why can't these be made with brass set-screws so as not to mar the finish of the barrel or the sight base???? (Don't shoot me - just asking..!!! <img border="0" title="" alt="[Eek!]" src="eek.gif" /> ) Best to ya!!!! John D. |

|

|

|

|

|

#8 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: Chandler Arizona

Posts: 3,540

Thanks: 1,342

Thanked 3,735 Times in 1,019 Posts

|

Hi John D!! Not a silly question at all! But, if the tool is made to the correct dimensions..the set screw kinda becomes redundant.... at least I have yet to see them on other tools! The best tools for the 1900 type .30 cal. have a notch machined in them, so that the sq. front sight block fits into, so that it can't go back and forth... lot'sa good ideas..making them affordable is the tough part... Best to you John D! til...lat'r...GT

|

|

|

|

|

|

#9 |

|

RIP

Join Date: Jun 2002

Location: South Side Virginia

Posts: 534

Thanks: 0

Thanked 1 Time in 1 Post

|

John D and GT,

The subject of marring the barrel could be corrected by controlling the finish if the interior of the Barrel Band and Post portions of the tool. These should be highly polished (and need not be hardened) so that no scratching will occur. . The flat end of the "rotating driving anvil" must be hardened to RC 58 or harder and have a mirror polish. in which case there will only show a very small burnished spot on the end of the dovetail sight base. Which in itself would be almost unseen. And if this be too objectionable then the anvil must drive without rotating, which is a simple matter to correct by using a hollow internal threaded thimble driving a keyed, sliding anvil. In which there would still appear a small presure spot which would be difficult to see with the unaided eye. Incidentally; Hard scrubbing of any soft metal on the sight dovetail or any portion of the weapon will transfer some of the softer material to the point where it contacts and result in some discoloration. So I would feel uneasy to try anything but a hardened and polished sliding anvil. PS: one final look at the tool shown appears that the anvil may be a sliding anvil, internally separated from, but driven by, the driving screw JMO ViggoG |

|

|

|

|

|

#10 |

|

User

Join Date: Jun 2002

Location: The USA

Posts: 5,919

Thanks: 0

Thanked 7 Times in 5 Posts

|

Noticed this fellow offers a similar tool for the P-38, as well...

Thanks for the tip, Guisan ! Regards, Pete... |

|

|

|

|

|

|