upload photo | donate | calendar

|

my profile |

register |

faq |

search upload photo | donate | calendar |

|

|

#5 |

|

User

Join Date: Oct 2007

Location: Maryland

Posts: 368

Thanks: 49

Thanked 140 Times in 61 Posts

|

Yes it does Ron. I think that many don't realize just how much work. The pictures clearly show just how much Quality is poured into the workmanship.

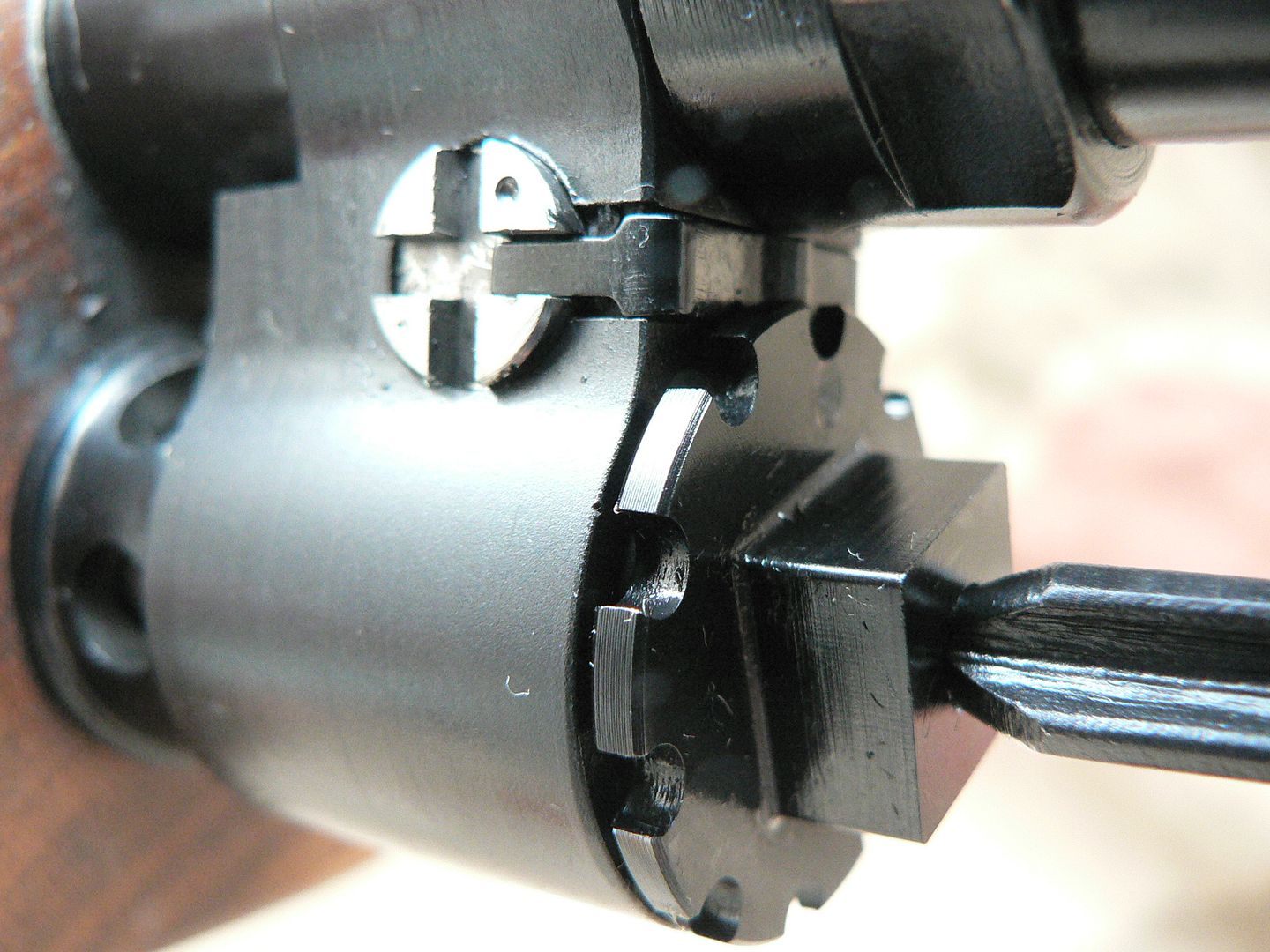

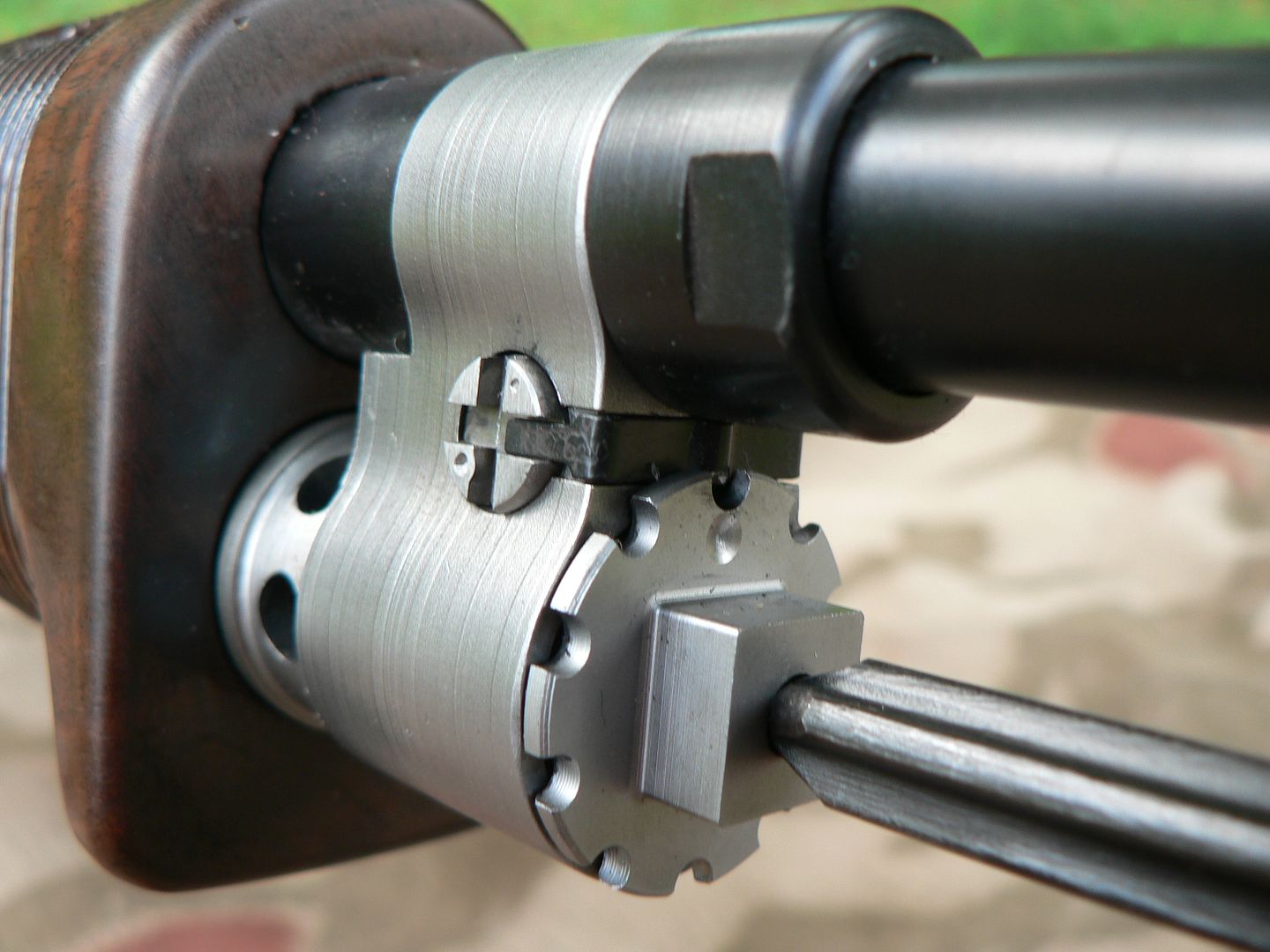

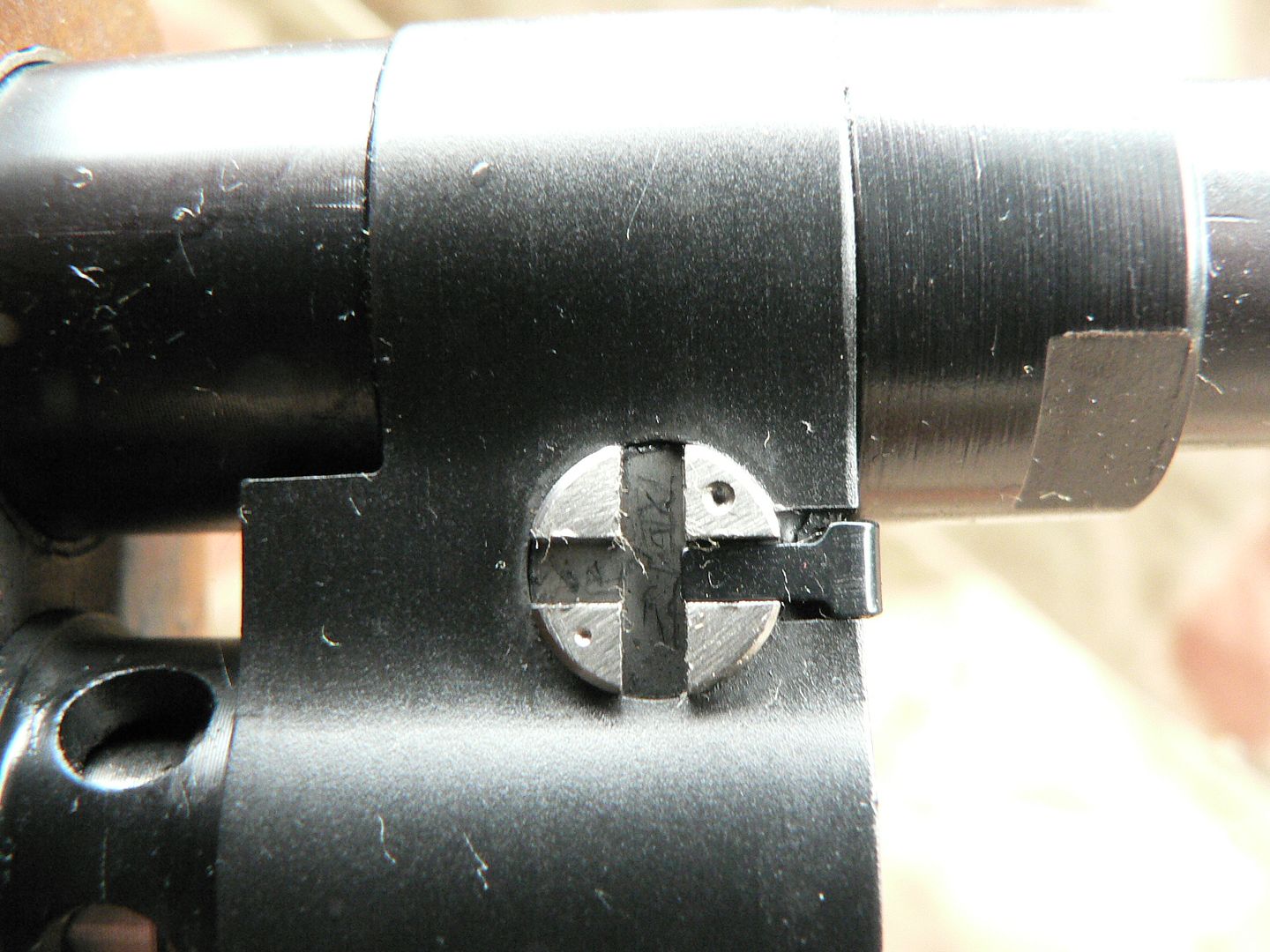

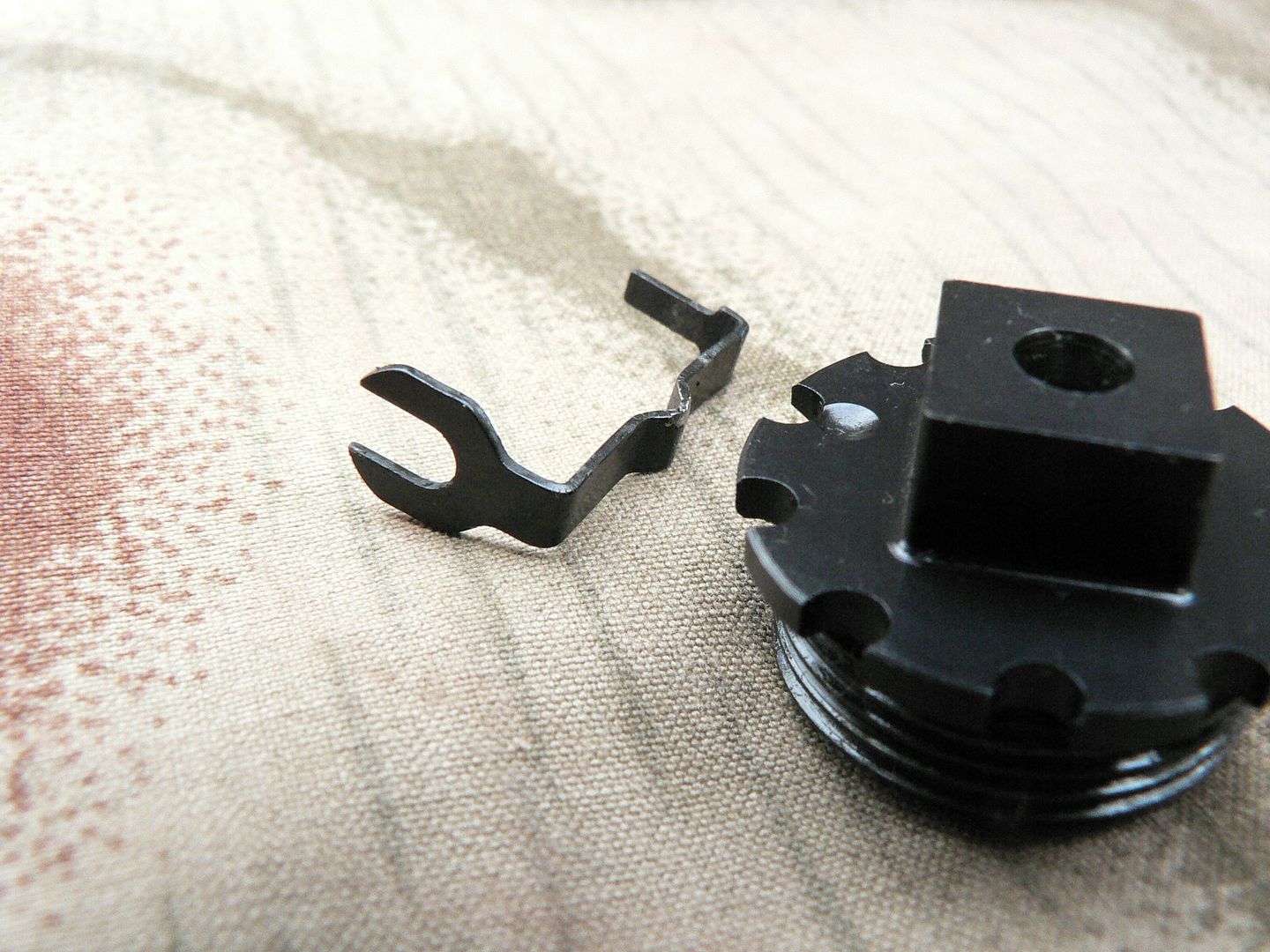

Picking up where we left off, let's take a look at the spike bayonet:  This part was not made by SMG for some reason nor is it supplied with the rifle. It started life as a much longer French made MAS 36 bayonet and was cut down to the proper length and blued to match the rifle by SMG. If you want one, YOU have to find one of these old and relatively obscure bayonets and YOU have to buy it and send it into them for modification. This rifle is a pretty complex piece of machinery and SMG figured out how to make every single part yet they don't make the bayonet. I must say that I don't quite understand the reasoning behind that one but that's just the way it is. The original German bayonet was copied from the MAS 36 too. Anyways, notice that there is a nub sticking up off the shaft both in front of and behind the knurled part of the shaft. These nubs are actually the ends of a spring loaded rocking bar concealed within the bayonet and are sticking out of holes cut in the shaft of the bayonet. They serve as the locking lugs that hold the assembly locked in either the deployed or the stowed position. Push down on one nub and the bar inside rotates pulling the other nub inside. The mounting tube that the bayonet fits into is part of the front sight base and is shown here hanging underneath the barrel:  Below the mounting tube is a smaller ring that serves as the attachment ring for the sling carabiner (we'll look at the sling later). To mount/deploy the bayonet, you simply insert the rear of it into the mounting tube and push until it clicks into place. The knurled part of the shaft will stop the bayonet from being pushed further rearward and the rear locking nub will keep it from being pulled forward. Here's what it looks like deployed:  It doesn't look very substantial but I guess it's better than nothing. Once locked in place, the bayonet will freely rotate in the mounting tube. To remove the bayonet, press the forward locking nub into the shaft and pull the bayonet forward and off the rifle. To stow the bayonet, simply insert it into the mounting tube tip first and slide it rearward until it locks. Again, the knurled ring will stop its rearward movement and the front locking nub will hold it from sliding forward. As you are stowing the bayonet, notice that the tip engages a hollowed out area in the gas plug shown here:  The tip of the bayonet is seen on the lower right of the picture. The reason for this is two fold. First, it helps stabilize the bayonet when stowed. Second, it keeps the shooter from sticking himself while using the rifle. We only want to stick the enemy! Here is a shot of the spike just about to engage the gas plug:  I'm getting a little excited for some reason..... Here is a good close-up shot with the bayonet stowed showing the mounting tube sandwiched between the knurled ring and the front locking nub:  Also of note in the above picture is the sling carabiner affixed to the attachment ring. One last stowed bayonet detail shot showing the rear of the spike protruding out under the muzzle brake:  Notice the contrast between the many scratches, dents and dings on the old surplus bayonet compared to the virtually flawless machining on the new muzzle brake. Remember....I love that muzzle brake! It worked so well that the Swiss copied it on their ZFK-55 sniper rifle and used it on many of their prototype weapons in the 50's too. Next up is the bipod. The FG42 was to be a multi-purpose weapon that would replace the submachine gun, rifle and light machine gun. One of the things necessary for it to fulfill the LMG role was a bipod. But being that the rifle was intended for use by airborne troops, it was designed light to save weight. Both proving grounds tests and use in the field proved that it was designed too light and was prone to failure but they kept on making it light anyway. The original was made of pressed steel but remember that SMG doesn't have the capacity to produce stamped parts. To replicate its many contours and details by machining would be neither cost nor time effective. So, SMG decided to outsource the legs (the rest of the bipod assembly is made of steel in shop) and decided on cast aluminum legs made by Shoei, a company that produces a non firing replica of the FG42. Now, if the original stamped steel bipod legs wouldn't stand up to the rigors of combat, I'm sure that I won't be doing push up or drop tests on the aluminum one because I'm sure it would fail. The good news here is that they seem to be plenty stout enough to last a lifetime of noncombat use. It is also notable that the Swiss considered aluminum to be a good enough material for use on the SIG 510, their standard issue battle rifle for approximately 35 years:  Let's take a look at how the bipod functions by flipping the rifle over and looking at the bottom of the bipod mounting yoke:  Here we see the right leg stowed and the left one deployed. Notice that the screw which holds the right leg to the yoke is peened in place so that it won't back out. You can see a notch cut in the bottom of the yoke for the spring loaded leg detent to lock into when the leg is folded down and you can see the spring loaded detent currently engaged in a similar notch in the rear of the yoke. Here is another picture showing the right leg deployed:  The notch in the rear of the yoke is clearly visible. The bipod yoke will not swing all the way around the barrel, being stopped by the legs hitting against the bayonet mounting tube Moving back the barrel, we come to the gas block:  The one shown is not my rifle but belongs to a friend of mine. I chose this picture for two reasons. First, it illustrates that the various parts on the rifle are available in three different finishes. These are blued (barrel and gas block retaining nut shown), phosphate (not shown but of the typical rough textured greenish gray) and bare steel (gas block and gas plug shown). The second reason for choosing this picture is that it makes distinguishing between barrel, gas block and gas block retaining nut a simple task. The barrel has a step machined into it that the rear of the gas block rests against. There is also a flat area on the barrel that is matched by a similar flat area on the block to keep it from spinning on the barrel. The gas block retaining nut is screwed down against the gas block and is held fast by torque and locktite that was pre-applied to the threads. Like the muzzle brake adapter, this is not meant to be disassembled unless you have the proper tools and know EXACTLY what you are doing. So guess what we won't be doing here.... Sticking out the side of the gas block with a "+" cut into it is the stainless steel gas regulator used to adjust how much gas is bled off to cycle the action. We'll take a closer look at that in just a bit. The black strip fitted into one of the regulator slots and wrapping around the front of the gas block is a piece of spring steel called the retaining spring and it serves two purposes. First, it locks the regulator from turning and second, it keeps the gas plug from loosening until you want it too. The gas plug is the crenelated disk on the front of the gas block with the tip of the bayonet sticking into it. It is threaded into the block and is removed for cleaning of the gas tube. Now that we know what's what here, lets switch back to the gas block assembly on my rifle and look at some of the parts in more detail. First, we'll check out the gas plug. To remove it, remove the bayonet. Then fit a wrench over the square lug sticking out the front of the plug and turn it counter clockwise. As you turn, it will click as the crenelations pass over the raised part of the retaining spring. Once it threads out to the point where the retaining spring no longer hits the little notches in the plug, you can turn it by hand until it comes loose. Here's the front of the plug after removal:  Notice the little dot at the top of the gas plug. This corresponds to a notch cut out of the back shown here at the top:  This notch must be aligned with the bottom of the gas regulator upon reassembly so that gas tapped from the barrel during firing can flow into the gas tube and push against the front of the stainless steel piston. If it is not aligned, you will have a single shot rifle because the gas will be effectively turned off. So, when screwing the gas plug in during reassembly, make sure that the dot on the front of the gas plug faces up as shown three pictures above. IMPORTANT: DO NOT crank the gas plug down tight. The dot will be pointing up BEFORE the plug is tight against the gas block. At this point, you will be able to wiggle the gas plug a little bit. That's how it's supposed to be. Here's the side of the gas plug showing the threads:  Gas block with plug removed showing the front of the stainless steel piston:  Here's a closer look at the right side of the stainless steel gas regulator:  Notice that it has two dimples on it, a large one for more gas(upper right) and a small one for less gas (lower left). Whichever one is positioned on the upper right is the current setting. So, in this case, the regulator is set for more gas (much like me). It should fire on less gas just fine but I haven't tried it yet ( I will be though). To adjust the regulator, the retaining spring must be removed. This is accomplished by pushing the spring forward from the LEFT side of the gas block. Pushing or pulling the spring from the right side WILL damage the spring. So let's look at the left side:  What we're seeing here is the other side of the regulator protruding from the gas block. It has a notch cut into it for the retaining spring to fit into. So, we use a small piece of wood or brass punch (if you are worried about scratching your finish) or a screwdriver/bullet tip (if you aren't worried about your finish) and push the retaining spring forward out of the groove. The manual says to do this with the gas plus partially installed so that you don't push your spring entirely off and lose it but we're taking it completely off here. Once the spring is no longer engaged with the slot on the right side of the regulator, you can insert a screwdriver into that slot and easily turn it where you want it. After setting the regulator, carefully seat the spring by again pushing on the left side. Here's the spring removed from the rifle:  Here's the gas block with the spring removed:  The spring slot has a high and a low area so that the spring seats properly and works reliably. And photobucket decided to die on me so that's it for tonight! I guess I'll try again later..... |

|

|

|

| The following member says Thank You to Wilhelm for your post: |

|

|