upload photo | donate | calendar

|

my profile |

register |

faq |

search upload photo | donate | calendar |

|

|

#1 |

|

User

Join Date: Oct 2005

Location: Canton Bern

Posts: 68

Thanks: 0

Thanked 0 Times in 0 Posts

|

I was busy yesterday giving my shooter a spring refurbishing using the Wolff assortment, all was well until I finally got to fitting the new mainspring.

The old one came out easily, and I turned to the tutorial on this site to put the new one back in. Using the drift pin and pliers technique to compress the spring such that the end was hooked by the guide pin hook was tough, even when shouting PAAAAAAAAAAAAAAAARRRAAAAAAABELLUUUUUUM, as recommended by the tutorial  This was a new standard spring, who knows what it would be like for the extra strength one This was a new standard spring, who knows what it would be like for the extra strength one  There must be an easier way says I.....need more mechanical advantage..... Then I lay eyes on my turret reloading press, aye, that big lever and ram there give a nice mechanical advantage, could it work? So I put the head of the spring guide and spring up into the seating die (45ACP) that happened to be on the press and rested the other end of the spring on the ram, with the edges just around the primer chute, which is incidently wider than the guide pin stem. Levering up the ram slowly with one hand, and keeping the spring in line with the other hand compresses the spring up just beyond the hook of the guide pin with no sweat and no bad words  Then keeping everything compressed you just angle the guide pin so its hook catches the end of the spring, and there you have it. Then keeping everything compressed you just angle the guide pin so its hook catches the end of the spring, and there you have it.

|

|

|

|

|

|

#2 |

|

User

Join Date: Jan 2006

Location: Down The Shore

Posts: 245

Thanks: 1

Thanked 6 Times in 4 Posts

|

Fabien,

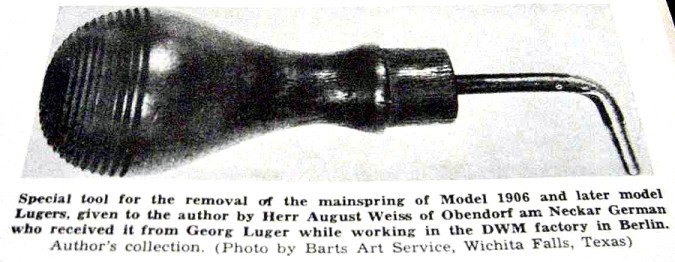

Glad to hear that you found an easier method to install a Luger mainspring. I fought with my first mainspring a few months ago. I made an inquiry on this website about the tool that they used at the factory. Someone posted a photo of the factory tool and I made a copy. I started with a $4 awl from Loweâ??s. I cut the tip off and ground about �¼ inch of the taper into a diameter that fit into the guide rod hole. Then I heated and bent it. When I tried it I could not believe how much better it worked than the method that is recommended on this website. I literally had the spring out and back in within a minute or so with little to no struggle.  Here is a picture of the tool that I made. Chris

__________________

The very atmosphere of firearms anywhere and everywhere restrains evil interference - they deserve a place of honor with all that's good. George Washington |

|

|

|

|

|

#3 |

|

Lifer

Lifetime Forum Patron Join Date: Dec 2004

Location: Sonoma County CA

Posts: 244

Thanks: 5

Thanked 34 Times in 17 Posts

|

I did the tutorial also and worked great the first time. The second tine it was a little different. I then remembered a post about putting the hook as high as easily done then holding the spring and screw the part the rest of the way to hook over the end of the spring. Nice and quit, no yelling and the wife did not know I was playing.

Jerry |

|

|

|

|

|

#4 |

|

User

Join Date: Oct 2005

Location: Canton Bern

Posts: 68

Thanks: 0

Thanked 0 Times in 0 Posts

|

Yup, the rest of the tutorial steps was easy, I was just determined to find an easier way of getting the guide-mainspring assembly together, since I don't have the machinery to make that tool.

|

|

|

|

|

|

#5 |

|

Patron

LugerForum Patron Join Date: Jun 2002

Location: POB 398 St.Charles,MO. 63302

Posts: 5,089

Thanks: 6

Thanked 737 Times in 484 Posts

|

I like the reloading press idea, if I had one, but I usually just wind the recoil spring on its guide, by turning the guide with a rod thru the hole in the bottom. TH

|

|

|

|

|

|

#6 |

|

User

Join Date: Apr 2005

Location: Virginia

Posts: 563

Thanks: 1

Thanked 34 Times in 27 Posts

|

I like the idea of the modified awl; I am going to make one and test it outâ??thanks for the picture.

I came up with a simple method years ago that works great also. The problem is getting the mainspring compressed and then that hook through the center of the frame, that hook tends to hang up because itâ??s under so much tension. I run a small diameter wire loop through the top of the frame, latch the hook to it and simply pull the hook into position and in the process compress the springâ??the entire assemble slides into place with easeâ??cut the wire loop and then latch the hook. If you donâ??t want to make a tool, I highly recommend this method. Vern |

|

|

|

|

|

#7 |

|

User

Join Date: Jan 2006

Location: Down The Shore

Posts: 245

Thanks: 1

Thanked 6 Times in 4 Posts

|

Vern

Here are photos of the original tools that I copied. Let me know how your tool works when you try it. Chris

__________________

The very atmosphere of firearms anywhere and everywhere restrains evil interference - they deserve a place of honor with all that's good. George Washington |

|

|

|

|

|

#8 |

|

User

Join Date: Jan 2006

Location: Down The Shore

Posts: 245

Thanks: 1

Thanked 6 Times in 4 Posts

|

I was bored tonight so I decided to make a video of the installation tool in action. Enjoy.

Here is the link to the video: http://www.youtube.com/watch?v=PjIXIielj8Q Chris

__________________

The very atmosphere of firearms anywhere and everywhere restrains evil interference - they deserve a place of honor with all that's good. George Washington |

|

|

|

|

|

#9 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,156

Thanks: 3,003

Thanked 2,309 Times in 1,098 Posts

|

Chris, what is the filetype for the video... it is slightly out of focus, but very well illustrates the use of such a tool for mainspring replacement and I am sure it will be helpful to all members who wish to do so... If you post a direct link to the video or email it to me, I will post it permanently on the forum for all to use... the location where you posted it will eventually delete the file...

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#10 |

|

User

Join Date: Jan 2006

Location: Down The Shore

Posts: 245

Thanks: 1

Thanked 6 Times in 4 Posts

|

John,

The file was recorded on my cell phone and is in 3GPP2 format. I copied the file to my computer and can view it with Quicktime. I tried to email the file to you but your profile does not allow e-mail from this forum. If you send me a PM with your e-mail address I will send the file to you. The file is 1.2MB. If you are willing to wait a week I will redo this with a better camera and a real tripod. I am on vacation until next Tuesday (Gettysburg PA then College Park, MD) Thanks, Chris

__________________

The very atmosphere of firearms anywhere and everywhere restrains evil interference - they deserve a place of honor with all that's good. George Washington |

|

|

|

|

|

#11 |

|

User

Join Date: Jun 2002

Location: NC - USA

Posts: 1,239

Thanks: 0

Thanked 19 Times in 7 Posts

|

Chris,

Good start . . . . and could be very helpful to others. Hope you are able to make a better video for the Forum reference area. Would be helpful if you could add audio. Thanks for your help. Luke

__________________

"Peace, if possible; truth, at any cost." . . . Martin Luther |

|

|

|

|

|

#12 |

|

User

Join Date: Sep 2006

Location: Nashville, Tennessee area

Posts: 263

Thanks: 5

Thanked 3 Times in 3 Posts

|

Here is a method of mainspring installation that might be novel. With the usual methods, the hardest part is the spring compression, and maybe not getting hurt.

This method is SAFE, easy, and takes no special tools. Before installing the spring or guide in the frame, I assembled them to a compressed state by this method. I placed the guide inside the mainspring, and by hand, hooked the end over the nearest coil inside the spring. Then using a jeweler's file handle, screwdriver shaft, or similar thin rod to turn or hold the guide rod's plug end, and gripping the spring with my hand, (for tender hands, you could use gloves or a piece of leather,) I worked the guide hook up the spring coils, rotating the spring and working the hook up the coils as it were threading a screw. It became difficult near the top, but by making sure the spring and guide were rotating at the bottom where the plug is, and alternating with moving the hook slowly at the top until it had come to the top of the spring and the entire spring was compressed under the guide rod's hook. The hook keeps the spring comressed by degrees this way, and avoids the potential damage to skin or eyes of a sudden release of compressed tension from an untrapped spring.  > > > > > > turn the screwdriver / guide rod, while holding the spring  > > > > > > a few more turns....  Then it was easy to place the spring and guide assembly inside the frame without fighting the spring, positioning the hook to nearly contact its home on the lever. Turn the gun upside down on its ears, on a smooth hard surface that will not mar the frame finish. Now with a stiff metal rod, ( that jewelers screwdriver shaft works well ) inserted into the guide rod's plug end hole, push the guide rod a bit more comressed, and manouver the hook onto the lever. Making sure the hook stays hooked on the lever slowly release pressure on the guide rod until everything settles into place correctly. |

|

|

|

|

|

|