upload photo | donate | calendar

|

my profile |

register |

faq |

search upload photo | donate | calendar |

|

|

#1 |

|

User

Join Date: Jan 2006

Location: Down The Shore

Posts: 245

Thanks: 1

Thanked 6 Times in 4 Posts

|

I installed a Wolff mainspring for the first time today. It took about fifteen minutes to install the 36 lb. spring. I tried to follow Thorâ??s directions but whenever I tried to start the main spring into the frame (step 6); the guide rod would come unhooked from the mainspring. In the end I wound up compressing the spring in the frame. Is there a trick to step 6?

I would think that the Germans did not have people in the Luger factories installing these springs armed with only a drift pin and pair of pliers. I assume that some sort of tool was used. I have read several posts where people mention tools to install mainsprings but no photos are posted. Did the Germans have a main spring installer tool and if so can someone post some photos of one? Thanks, Chris |

|

|

|

|

|

#2 |

|

Moderator

Lifetime LugerForum Patron Join Date: Oct 2002

Location: Europe

Posts: 5,045

Thanks: 1,034

Thanked 3,934 Times in 1,196 Posts

|

Hi,

What I did was take a takedown tool (repro), place it on an opened pair of plyers. Place the spring on the hole of the takedown tool, the hole was slightly smaller than the width of the spring. Pushed in the guide rod from above, using a small screwdriver through the hole in the guide rod as a lever. This made it easier to push the lip on the end of the guide rod past the end of the coil spring, using the extra space under the takedown tool. If the takedown tool is caught between the spring and the guide rod lip, it can be wiggled out of the way quite easily. Placing the spring and rod in the frame was actually the easy bit. |

|

|

|

|

|

#3 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,150

Thanks: 3,003

Thanked 2,304 Times in 1,096 Posts

|

Let me see if I can describe my method adequately to allow someone to follow it.

STEP ONE-PUT ON EYE PROTECTION! I Can't overemphasize this step. STEP TWO-place yourself in a small confined space without a rug (that you can easily search if the parts get away from you and SSSPPPRRROOOIIINnnGGGG across the room, at least you will be able to find them. To get the spring on the guide, I insert the guide into the spring in the end where the coils are most tightly wound and compress the spring as much as I can with my fingers until I can catch the hook on the spring... ...from there I wind the spring by hand (or with a pair of non-marring pliers until the hook has passed through the other end and hooked onto the outside of the last coil... ...the spring/guide combination is then inserted top first into the frame with the hook aligned properly to engage the mainspring lever... ... at this point I insert a large handle/small shaft phillips screwdriver that will fit into the hole in the bottom of the spring guide ...now you have some choices... I can manage without a vise, but I recommend a soft jaw non marring vice to amateurs to hold the frame while completing this operation... BUT here is how I do it... I place the frame top up in front of me on a bench...and using my thumbs, I press down on the "ears" while holding on to the screwdriver and using the screwdriver I compress the spring until the whole assembly in in the frame... then I make sure of the orientation of the hook, and using the same method described, I compress the spring once again using only my screwdriver hand, and manipulate the hook and lever until they are mated... then I gently relax the spring tension provided by the screwdriver. I make no guarantees for anyone else, but I have never lost a spring, an eye, or a spring guide using this method and it only takes me a minute or so to install one... Then if I was a beer drinker, which I am not, it would be miller time... Keep this in mind... Most springs have been in their Luger for somewhere between 50 and nearly 100 years. They have probably collected a few dust bunnies, and some powder residue, some grime, and petrified grease... This operation probably only has to be done once or twice in the life of a Luger... Detailed stripping is rarely necessary unless you get some foreign substance in the nooks and crannies of your Luger... or if you are having the gun refinished. If you are concerned about dirt, FIRST REMOVE THE GRIPS, get yourself an aerosol can of carbureator or brake drum cleaner and devastate the dirt... wipe the gun down... and then relubricate... Unless you are experienciing one of the events mentioned above, or are replacing the tired spring, most Luger owners will never have to accomplish this engineering nighmare of a feat...

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#4 |

|

Super Moderator

Eternal Lifer LugerForum Patron Join Date: Jun 2002

Location: North of Spokane, WA

Posts: 15,915

Thanks: 1,989

Thanked 4,506 Times in 2,080 Posts

|

I too have wondered Chris, there HAS to have been a tool. As far as I know and I have about 20 luger books, I have never seen a picture or description of a speciifc tool to do this.

I would guess it was some kind of y shaped tool that you placed the end of the spring in and reset the spring, but I don't know... Ed

__________________

Edward Tinker ************ Co-Author of Police Lugers - Co-Author of Simson Lugers Author of Veteran Bring Backs Vol I, Vol II, Vol III and Vol IV |

|

|

|

|

|

#5 |

|

Patron

LugerForum Patron Join Date: Jun 2002

Location: POB 398 St.Charles,MO. 63302

Posts: 5,089

Thanks: 6

Thanked 736 Times in 483 Posts

|

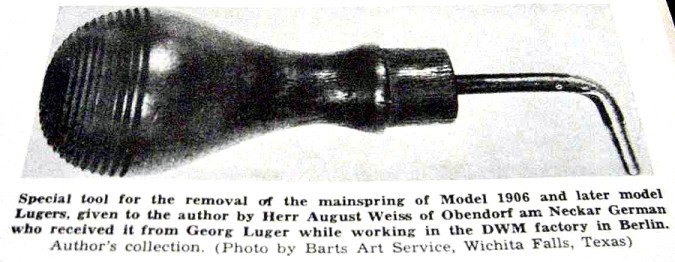

Chris & Ed, If memory serves me OK, I seem to recall seeing a photo somewhere of a wood handled "leather all like" tool with a hook on the steel tip, that was used for this purpose. TH

|

|

|

|

|

|

#6 |

|

User

Join Date: Jan 2006

Location: East Central Florida

Posts: 367

Thanks: 1

Thanked 7 Times in 2 Posts

|

I thought about trying to make one from parts that anyone can buy at a hardware store. If I have any luck I'll post my findings and instructions on how to.

__________________

"When the people fear their government, there is tyranny; when the government fears the people, there is liberty." |

|

|

|

|

|

#7 |

|

RIP

Join Date: Jun 2002

Location: Southeast Texas Swamp

Posts: 2,460

Thanks: 2

Thanked 165 Times in 64 Posts

|

Two Luger spring tools: The top picture is self explanatory. The second pic shows a home-made tool. The space between the two metal arms is just wide enough to straddle the grip frame. The rod is place thru the hole in the spring guide, and the tool is levered against the wide part at the bottom of the frame where the grip screws go to compress the spring.

__________________

TRUMP FOR PREZ IN '20! |

|

|

|

|

|

#8 |

|

Patron

LugerForum Patron Join Date: Jun 2002

Location: POB 398 St.Charles,MO. 63302

Posts: 5,089

Thanks: 6

Thanked 736 Times in 483 Posts

|

Hugh, Thanks for posting photos. The top one is the one I recall seeing. The bottom tool is useful for connection the recoil spring guide to the recoil lever, once the spring & guide are INSIDE the frame. I had several all steel ones made up for this purpose about 30 years ago. I still have a couple left @$40 each + $5 S&H, if anyone is interested. Tom

|

|

|

|

|

|

#9 |

|

User

Join Date: Jan 2006

Location: Down The Shore

Posts: 245

Thanks: 1

Thanked 6 Times in 4 Posts

|

I took the image of the factory tool and made a copy today.

I started with a $4 awl from Loweâ??s. I cut the tip off and ground about �¼ inch of the taper into a diameter that fit into the guide rod hole. Then I heated and bent it. When I tried it I could not believe how much better it worked than the way I was trying before. I literally had the spring out and back in within a minute or so with little to no struggle.  Thanks for the valuable information. Chris  |

|

|

|

|

|

#10 |

|

Moderator

2010 LugerForum Patron Join Date: Jun 2002

Location: Santa Teresa New Mexico just outside of the West Texas town of El Paso

Posts: 6,988

Thanks: 1,067

Thanked 5,099 Times in 1,676 Posts

|

Shadow,

Good looking tool that you have fabricated and obviously you have learned how to use it. Georg knew what he was doing! I did the same thing with an awl from Sears (prettier wood, but about twice the price)

__________________

If it's made after 1918...it's a reproduction |

|

|

|

|

|

#11 |

|

User

Join Date: Jun 2002

Location: mt

Posts: 38

Thanks: 13

Thanked 31 Times in 9 Posts

|

|

|

|

|

|

|

#12 |

|

Super Moderator

Eternal Lifer LugerForum Patron Join Date: Jun 2002

Location: North of Spokane, WA

Posts: 15,915

Thanks: 1,989

Thanked 4,506 Times in 2,080 Posts

|

Very interesting John, makes you wonder if its a copy or real!

Ed |

|

|

|

|

|

#13 |

|

User

Join Date: Jun 2002

Location: mt

Posts: 38

Thanks: 13

Thanked 31 Times in 9 Posts

|

I agree Ed. The thing is surprisingly heavy, and the handle is made of either very dense wood, or some other hard stuff.

John |

|

|

|

|

|

#14 |

|

Super Moderator

Eternal Lifer LugerForum Patron Join Date: Jun 2002

Location: North of Spokane, WA

Posts: 15,915

Thanks: 1,989

Thanked 4,506 Times in 2,080 Posts

|

John, you have to let me root through that "pile" of worthless "extensive parts"

Ed |

|

|

|

|

|

#15 |

|

User

Join Date: Jun 2002

Location: mt

Posts: 38

Thanks: 13

Thanked 31 Times in 9 Posts

|

Well Ed, it is fun to finally put a handle /name/function on some of these things that have been kicking around for a number of years.

John |

|

|

|

|

|

#16 |

|

Super Moderator

Eternal Lifer LugerForum Patron Join Date: Jun 2002

Location: North of Spokane, WA

Posts: 15,915

Thanks: 1,989

Thanked 4,506 Times in 2,080 Posts

|

That is for sure, had Glen over and he said, oh, you have some 1903 Springfield parts... I put them on e-bay, made some money, I didn't know what they were and hard to list if you don't have a clue... Just have to have the right expert know what the heck those parts are!

Ed |

|

|

|

|

|

#17 |

|

User

Join Date: Jan 2006

Location: Down The Shore

Posts: 245

Thanks: 1

Thanked 6 Times in 4 Posts

|

John,

Could you post some photos of any other luger tools that you have in the collection? Thanks, Chris |

|

|

|

|

|

#18 |

|

User

Join Date: Jun 2002

Location: mt

Posts: 38

Thanks: 13

Thanked 31 Times in 9 Posts

|

Chris,

Well, I will stir the pile and see what comes up. However, I canâ??t think of any other exotic tools for lugers. Of course, the main spring tool was just an unidentified weird object until now. John |

|

|

|

|

|

|