upload photo | donate | calendar

|

my profile |

register |

faq |

search upload photo | donate | calendar |

|

|

#1 |

|

Moderator

2010 LugerForum Patron Join Date: Jun 2002

Location: Santa Teresa New Mexico just outside of the West Texas town of El Paso

Posts: 6,986

Thanks: 1,065

Thanked 5,088 Times in 1,674 Posts

|

Here are some views of the flat laminated spring found in the early 1900 and 1902 Lugers.

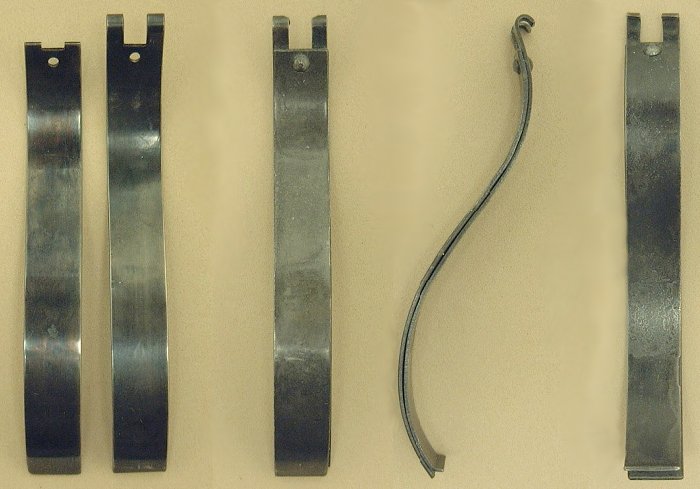

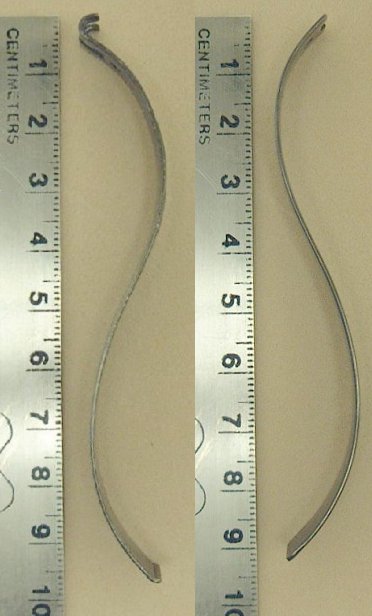

The mainspring consists of two laminations that are riveted together. The longer leaf includes the hook that engages the S-shaped transfer link connected to the toggle.  The laminated mainspring is difficult to find, so occasionally you will encounter a gunsmith replacement that was made to restore a Luger to operational condition without regard to "cosmetics". The following example came from a 1900 Luger that made its way from Old Mexico across the border into Texas. It is hand forged and has the same aesthetics as homemade soap, but it works! The ingenuity and resorcefulness of craftsmen is always a source of wonder.  As noted by Levallois, the shape of the mainspring varies and what may function in one Luger may not be "tuned" to another. The next photo shows the different curvatures from left to right of the individual leaves, two original examples, and the hand forged example.  The actual dimensions of the components of the mainspring can only be estimated from a photo. The true dimensions would have to be determined by having the parts in hand. In addition to the dimensions, the tensile strength of the springs would have to be measured. The following illlustration shows the relative dimensions of the components, but I would guess that it falls far short of that necessary to make a reproduction.

__________________

If it's made after 1918...it's a reproduction |

|

|

|

| The following member says Thank You to Ron Wood for your post: |

|

|

#2 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,150

Thanks: 3,003

Thanked 2,304 Times in 1,096 Posts

|

Thanks Ron for a great photo essay on the early mainspring. From your photos it seems that the size of the "foot" on the longer spring also varies... does this foot play a role in keeping the lower end of the spring in place during operation? I imagine it does, and if I am correct, approximately what length would you consider optimum?

On my screen, it appears that the photo is approximately 1.5 to 1.6 times larger than life. Measuring the original spring's "pull" would seem to be a challenge... Once last question. Appoximately what thickness of spring steel are we dealing with here? are both leaves the same material or is one thicker than the other?

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#3 |

|

Patron

LugerForum Patron Join Date: Jun 2002

Location: POB 398 St.Charles,MO. 63302

Posts: 5,089

Thanks: 6

Thanked 736 Times in 483 Posts

|

John, You make an exc point: a couple of the springs shown in profile in one of Ron's photos, appear to be missing the "foot", which is essential to holding the spring into the frame. Without this bend at the bottom, the spring will lift and not allow the toggle to come back all the way. TH

|

|

|

|

|

|

#4 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,150

Thanks: 3,003

Thanked 2,304 Times in 1,096 Posts

|

Tom, does that mean it is possible that the spring already contained in 1900 discussed in the other AE thread might have a "foot" issue as a source of the problem?

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#5 |

|

Moderator

2010 LugerForum Patron Join Date: Jun 2002

Location: Santa Teresa New Mexico just outside of the West Texas town of El Paso

Posts: 6,986

Thanks: 1,065

Thanked 5,088 Times in 1,674 Posts

|

All the springs shown have a foot on the longer leaf, albeit it is a bit smaller on the disassembled mainspring. Both leaves are the same thickness on a 7.65mm spring. For the 1902 9mm spring, the long leaf is approximately 50% thicker than the 7.65mm spring but the short leaf is the same thickness for both calibers.

I will measure the thickness of the spring steel and get back to you.

__________________

If it's made after 1918...it's a reproduction |

|

|

|

|

|

#6 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,150

Thanks: 3,003

Thanked 2,304 Times in 1,096 Posts

|

Thanks Ron... Did you get my PM on this issue?

Now a question regarding the spring tension. I would imagine that the "pull" that this spring should have would be roughly equivilent to the same pull created by a coil spring Luger when compressed to the same length that it takes when the toggle is in the rearmost position. In order to get a quote on fabrication of these springs, I guess we would need to simulate the compression using a fishing scale or trigger pull scale... this would be easiest using the coil spring setup from a .30 caliber luger... which I don't own. Anyone out there equipped with an appropriate scale and a .30 caliber Luger who could determine this pull weight strength? I have found a company who will create a small quantity of prototype springs... to get a quote, they need dimensions, and specs. I believe that the photos taken by Ron Wood, (along with the width and thickness dimensions) combined with the estimate "pull" requirements may be enough for them to quote the manufacture of these springs... Any help would be appreciated... I am sure that in the near future, there will be a demand for these springs as the pistols that use them age.

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#7 |

|

RIP

Join Date: Jun 2002

Location: Southeast Texas Swamp

Posts: 2,460

Thanks: 2

Thanked 165 Times in 64 Posts

|

John,

I will measure my 1900's & 1906's when I get the chance, leaving for a gunshow in a few minutes---- Maybe someone will do it before I can. Both of my Lugers with the flat mainspring have considerable less resistance to pulling the toggle back than any of my Lugers with a coil mainspring.

__________________

TRUMP FOR PREZ IN '20! |

|

|

|

|

|

#8 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,150

Thanks: 3,003

Thanked 2,304 Times in 1,096 Posts

|

Thanks Hugh... I had a suspicion that the resistance would be less with this type of spring. Are both of your lugers that use this type .30 caliber? or is either 9mm?

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#9 |

|

Moderator

2010 LugerForum Patron Join Date: Jun 2002

Location: Santa Teresa New Mexico just outside of the West Texas town of El Paso

Posts: 6,986

Thanks: 1,065

Thanked 5,088 Times in 1,674 Posts

|

I received your PM and I am mulling over a reply. There are a bunch of factors involved and I want to think about it a bit. In addition to "pull weight" there may also be some pre-loading that needs to be considered. The pre-loading may already be covered by pull weight and length of the spring but it is going to take someone with a lot more mechanical engineering skills than I have to figure this out. Also as noted, there is significant variance in curvature of the springs even in the small sample I have posted. What is the correct configuration and which ones have already taken a "set" and may or may not be a candidate for a prototyping standard? There may be a requirement for a larger population sampling and I admit that I am loath to start taking the springs out of my collection pieces to increase the sample.

Perhaps these aren't significant factors and the spring company can address them with ease. But it never hurts to have most of the answers figured out up front.

__________________

If it's made after 1918...it's a reproduction |

|

|

|

|

|

#10 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,150

Thanks: 3,003

Thanked 2,304 Times in 1,096 Posts

|

Thanks Ron... appreciate the update while you are mulling over the issues.

I have been wondering what kind of breakage is normally experienced with these springs? I would imagine that the most common breakage might be the "hooks"... but if anyone has had one of these types of springs actually fail, I would sure like to know the manner in which it failed... Got soft? (what a terrible way to go!  ) )Snapped? (in what location?) Separated at the rivet? Since one of Ron's springs is actually a replacement made in Mexico out of 1 piece, instead of sandwiched leaves... I wonder how the original spring failed? ..finally does anyone know what kind of steel hacksaw blades are made of? I know a few old gunsmith's (unfortunately now deceased) who used to make rifle magazine follower springs out of them when an original couldn't be found. They look like they might be a good candidate for replacement stock to create new Luger springs.

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#11 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: Chandler Arizona

Posts: 3,485

Thanks: 1,283

Thanked 3,581 Times in 989 Posts

|

Hi to Ron, John and all... John, on the type of steel and the weight of the "pull" needed, you will find your options are thankfully limited... The original springs were made from a basic high carbon steel, probably comparable to 1075 spring steel, perhaps a bit higher in carbon, as they obviously had a high failure rate, which could be attributed to either brittle steel, or improper tempering.. To support this statement, now days, you have to have very special climate controlled conditions, and ovens, to properly heat treat and temper 1095 spring steel..... 1050 to 1075 small parts, you can temper and draw successfully with a torch... Your reproduction springs are going to fall into these ranges of steel, both from a production cost factor and a design requirement parameter... In essence, if you use the correct material, and build it to the exact spec's, and temper / draw (pigeon blue) it using todays modern methods,your springs tension will be automatically correct... I'm thinking 1075 annealed spring steel, and you'll have a better spring then they ever dreamed of making!! Best to all, til....lat'r....GT

|

|

|

|

|

|

#12 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,150

Thanks: 3,003

Thanked 2,304 Times in 1,096 Posts

|

GT... 1075 Flat Steel is what Brownell's stocks ... I just need to know what width the springs are so I can get the right size to experiment with. I think trying to make a spring from just the photos and measurements in this thread would be an interesting experiment.

Thanks for your input...

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#13 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: Chandler Arizona

Posts: 3,485

Thanks: 1,283

Thanked 3,581 Times in 989 Posts

|

Hi John, I see where Brownells has 1095 annealled, you might have to use this and get it professionally tempered.... The problem is getting 1075, or any other "annealed" spring steel! It is dead soft and easy to form and cut, it also has a grain you need to pay attention to, it runs linear with the sheet or coil... Then, when you have the final part shape, you have it heat treated, and then drawn back to the correct strength for the intended spring... The small quantity spring steel most often offered is unfortunatly, already tempered!! Soooo, to get what you need, you usually have to buy a minimum quantity coil of so many pounds and it cost several hundred dollars to start with... Making the springs is the easy part...finding the "annealed" spring steel in the exact thickness needed, is the hard part!!.... Has to be annealed to work with... and no, you can't anneal and retemper... too much work to get correct, if possible at all... I will certainly assist you if i can John... best to you, til....lat'r....GT

BTW John, you can compare compression by clamping one end of the flat spring to a flat surface and pressing down on the apex of the bend to a preset stop, with the whole works on a scale... do the same with your test samples, when you get then made, and the pounds of force needed should be close and comparable..... |

|

|

|

|

|

#14 |

|

Moderator

2010 LugerForum Patron Join Date: Jun 2002

Location: Santa Teresa New Mexico just outside of the West Texas town of El Paso

Posts: 6,986

Thanks: 1,065

Thanked 5,088 Times in 1,674 Posts

|

John,

I have owned 2 broken springs (one was in a gun and the other I picked up as parts, I didn't break them!). The hooks were both good. They were snapped about 1/3-1/2 way down from the hook. One had the main spring (with the hook) broken and one the auxillary spring. I salvaged the good main and good aux spring and riveted them together...worked great. I bought the disassembled spring in the photo that had been fastened together with a lousy makeshift rivet. The rivet had not been properly peened so the whole assembly was floppy. I will get around to putting a new rivet in it someday.  Once upon a time I needed an odd shaped flat spring for an old revolver. I didn't know diddly about steel types, but I found some steel shim stock at a machine shop that was the right thickness. It was in the white and cut relatively easliy so it must have been annealed. After cutting and bending it to shape and polishing it, I heated it to peacock blue and tried it. Got lucky the first time! This was an internal spring that worked the cylinder pawl so it did not have to be terribly exact in its performance. Just thought I would mention where I got the steel as a possible source.

__________________

If it's made after 1918...it's a reproduction |

|

|

|

|

|

#15 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,150

Thanks: 3,003

Thanked 2,304 Times in 1,096 Posts

|

Thanks Ron... how about leaf thickness and width?

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#16 |

|

Moderator

2010 LugerForum Patron Join Date: Jun 2002

Location: Santa Teresa New Mexico just outside of the West Texas town of El Paso

Posts: 6,986

Thanks: 1,065

Thanked 5,088 Times in 1,674 Posts

|

Hang on, it will be forthcoming.

__________________

If it's made after 1918...it's a reproduction |

|

|

|

|

|

#17 |

|

User

Join Date: Nov 2006

Location: North central Ohio

Posts: 41

Thanks: 0

Thanked 0 Times in 0 Posts

|

Greetings, Gentlemen,

I purchase 1075 annealed from Brownells in 12" lengths of different widths and thicknesses. If I need larger sizes I buy from McMaster-Carr. I make many different springs for my antique revolver restorations, and the 1075 from both sources work very well.

__________________

Regards, Ralph Boy, I love these old guns..... |

|

|

|

|

|

#18 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,150

Thanks: 3,003

Thanked 2,304 Times in 1,096 Posts

|

RalphH thanks so much for your input. Your advice is very helpful. Can we inquire about your procedures for shaping and tempering your springs made from this material?

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#19 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: Chandler Arizona

Posts: 3,485

Thanks: 1,283

Thanked 3,581 Times in 989 Posts

|

Hi RalphH and John, great source for the strips of 1075 annealed spring steel in McMasters-Carr, John, you should be able to get pretty close with their offerings... RalphH, Thanks for your info.. best to you, and good luck to all....til...lat'r...GT

|

|

|

|

|

|

#20 |

|

User

Join Date: Nov 2006

Location: North central Ohio

Posts: 41

Thanks: 0

Thanked 0 Times in 0 Posts

|

Greetings,

1075 is very soft and malleable in its annealed state. Cutting, filing, grinding and bending to shape is quite easy. It should be the same shape and dimensions as the original spring. Polish the surfaces that would be on the outside of the flex. You don't want any minute scratches or defects that might contribute to a fracture later. I use 1200 wet-or-dry paper. I use an electric furnace to heat treat. Mine was made by "Ney". It has a maximum temperature of 2000 degrees, and can be brought to temperature very slowly or quite fast. The temperature gauge is marked in 25 degree increments, and is extremely accurate. I bought it about 30 years ago from Brownells for $300.00. I place the soft spring in the cold furnace in a small steel pan. I bring the heat up to 1500 degrees slowly, remove the spring and quench in quenching oil. I turn off the furnace and let cool to 575- 600 degrees with the door slightly ajar. I quickly place the spring back in the oven and shut the door. It cools very slowly with the door shut. I return the following day and remove the spring. If I want it shiny, I polish with 1200 wet-or-dry and buff with Jewelers rouge. Spring is done. P.S. Brownells still sells the Neycraft 240V furnace, only now it's $750.00.

__________________

Regards, Ralph Boy, I love these old guns..... |

|

|

|

|

|

|