upload photo | donate | calendar

|

my profile |

register |

faq |

search upload photo | donate | calendar |

|

|

#1 |

|

Lifer

Lifetime Forum Patron Join Date: Feb 2009

Location: ...on the 'ol Erie Canal...

Posts: 8,208

Thanks: 1,425

Thanked 4,474 Times in 2,343 Posts

|

It's a slow day...

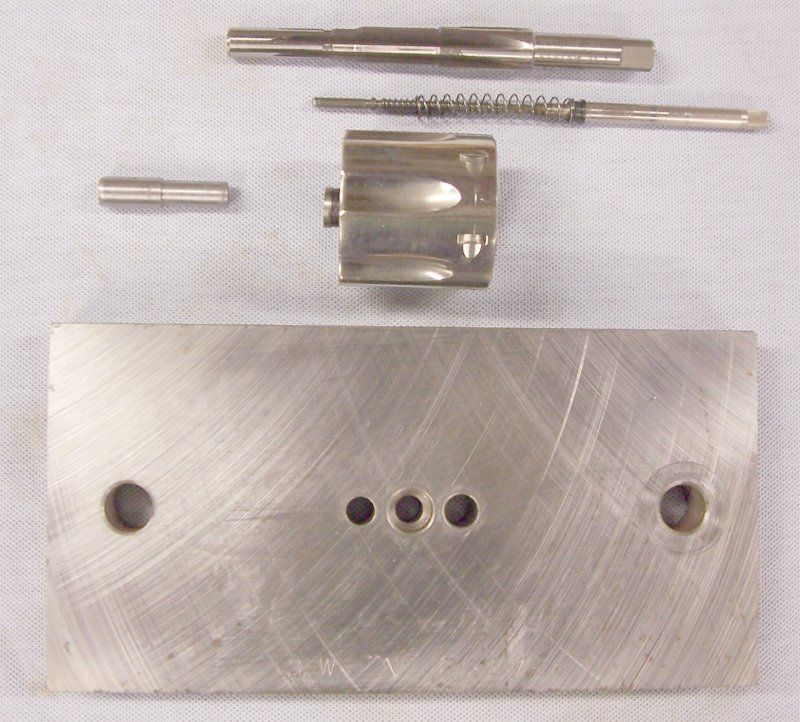

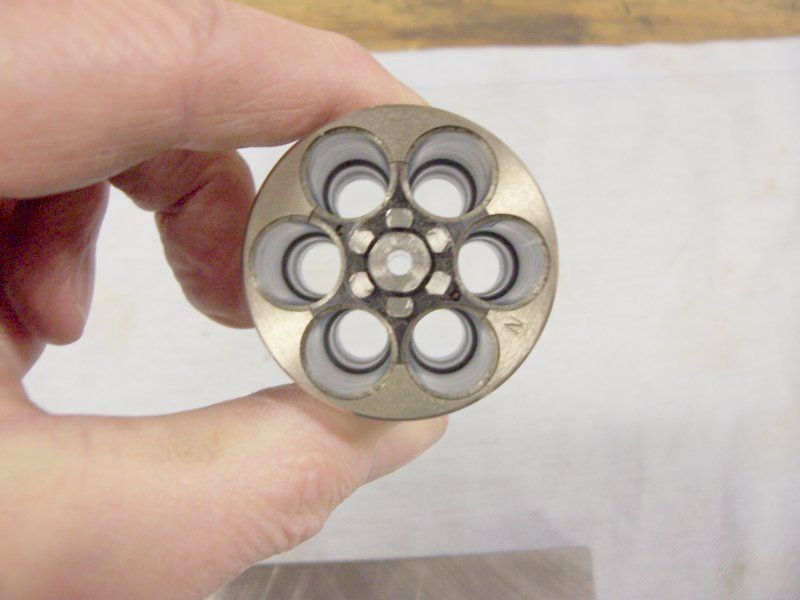

Cleaning out the trash in my basement and storage shed, I found this jig which I had made and used for re-chambering S&W N frame .357 magnum cylinders to a wildcat .357/.44 cartridge. I thought I'd do a quick & dirty write-up of it, as it turned out quite successful. Back in the 80's, a friend and partner of mine was interested in magnum pistols. Jim had a .45 Lar Grizzly Magnum auto; I had a .357 AutoMag and a .44 Ruger Blackhawk. On a lark, I ran a .44 magnum case through the .357 AutoMag reloading/sizing die. It looked 'cool', so I showed it to Jim. Jim had a blued 6" bbl .357 magnum S&W N frame and was enthusiastic, and I caught his enthusiasm. A co-worker of Jim's had a nickel S&W N frame .357 magnum, and he was only asking $325 for it...I bought it. Jim dug up a spare .357 magnum cylinder for his N frame from somewhere, and I started designing.   First thing was to get a reamer. Back then, the Clymer family owned the Clymer reamer business and would grind special/custom reamers for customers. Supply them with two dummy cartridges and a set of dimensions and they would grind a custom reamer for you. I did this and got my custom .357/.44 magnum reamer. I had a Bridgeport 2J mill back then, and made up this jig to hold the cylinder. The 3/4" steel plate is surface ground and bored to accept the cylinder spigot and a special pin to locate the cylinder. Basically, you bolted the jig to the mill table, aligned the hole in the right side to the mill quill, clamped the cylinder to the jig/table, and reamed the cylinder, with extractor left in place. Headspace was left the same as S&W had headspaced the .357 cartridge. Keep rotating the cylylinder until all 6 chambers had been reamed.     Cylinder timing was unaffected. The pin was an exact fit in the front of the cylinder and precisely centered the chamber for reaming. The N frame was also offered in .44 magnum as well as .357 (in fact, it was designed for .44 mag first and then offered in .357 by popular demand) so there was no question of the .357 cylinder being too thin or weak - it was the same .44 mag cylinder only bored for .357 - it was designed for .44 magnum pressures. I did my S&W and Jim's and IIRC at least one other...CRS and missing/non-existant receipts complicate my memories...Jim died young & suddenly some years ago, and his daughter took care of his estate. I don't know what happened to his cylinder. I still have mine, as well as a second .357 mag cylinder and a 4" barrel. The cartridges shot flat and fast, as you might expect, with a very satisfying hollow sounding noise. I loaded my cartridges conservatively, but Jim liked his hot. I had the only .357 AutoMag dies, so I loaded his. He'd shoot progressively hotter loads until the primer started to flatten...Then he'd say it was just right...And we'd run off a couple hundred.  This wildcat is similar to the .357 Bain & Davis but without the long taper. This cartridge gives more support for the bullet than the B&D. And I already had the AutoMag dies. Wildcatting was fun back then. We'd show up at the range, unload our stuff and start banging away. Me with the AutoMag and S&W, Jim with his Lar Grizzly and S&W. After about 15 or 20 shots, we'd look around, and there would be people hanging out of the clubhouse windows & doors to watch the fireballs...

__________________

I like my coffee the way I like my women... ...Cold and bitter...

|

|

|

|

| The following 13 members says Thank You to sheepherder for your post: |

|

|

#2 |

|

Patron

LugerForum Patron Join Date: Mar 2011

Location: Az.

Posts: 2,315

Thanks: 2,748

Thanked 998 Times in 733 Posts

|

Thank you very much for the photos, history, and how-to do it. I really get into the unusual I guess, and start thinking...what if?? It keeps me occupied and usually broke also. I guess I never could be totally satisfied with the run of the mill things. I am not sure that I made some better or worse, but I usually liked the outcome.

|

|

|

|

|

|

#3 | |

|

Lifer

Lifetime Forum Patron Join Date: Feb 2009

Location: ...on the 'ol Erie Canal...

Posts: 8,208

Thanks: 1,425

Thanked 4,474 Times in 2,343 Posts

|

Quote:

__________________

I like my coffee the way I like my women... ...Cold and bitter...

|

|

|

|

|

|

|

#4 |

|

Lifer

Lifetime Forum Patron Join Date: Feb 2009

Location: ...on the 'ol Erie Canal...

Posts: 8,208

Thanks: 1,425

Thanked 4,474 Times in 2,343 Posts

|

Jim was doing some .357/.45 sabot loads in his Grizzly; I don't recall if they worked out or not...I've tried to find the sabots that he used, they seem to have disappeared...He had a big bag of them; must have been a thousand...Slightly depleted...

The Grizzly .45 cartridge was a magnum; the grip and magazines were extended, front to back...Pachmayr made a special rubber grip for it, ugly as hell...Looked like two 1911 grips stuck on top of each other... The Grizzly auto itself was ugly...

__________________

I like my coffee the way I like my women... ...Cold and bitter...

|

|

|

|

|

|

#5 |

|

Patron

LugerForum Patron Join Date: Mar 2011

Location: Az.

Posts: 2,315

Thanks: 2,748

Thanked 998 Times in 733 Posts

|

|

|

|

|

|

|

#6 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,156

Thanks: 3,003

Thanked 2,309 Times in 1,098 Posts

|

Try using slightly smaller weight bullets in the .223's like bullets designed for the .22 Hornet. You may find using these round nose bullets to cure your feeding problems.

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#7 |

|

Lifer

Lifetime Forum Patron Join Date: Feb 2009

Location: ...on the 'ol Erie Canal...

Posts: 8,208

Thanks: 1,425

Thanked 4,474 Times in 2,343 Posts

|

I've been doing a lot of reloading lately, and also have some new acquisitions which I am getting the required die sets for. One will require two different die sets, and while browsing through an old COTW, I found the '44-357 Davis' cartridge listed. It's practically the same as my 357 Automag/44 S&W Magnum wildcat. Both differ from the 357/44 Bain & Davis by not having the long tapered neck.

I can't find any reference as to why the 357/44 Bain & Davis had the tapered neck. Extraction was never a problem, even with Jim's hot loads. Maybe just to make it different???  Just goes to show that great minds think alike. Separated by 30 or 40 years, but the same basic idea.

__________________

I like my coffee the way I like my women... ...Cold and bitter...

|

|

|

|

|

|

#8 |

|

User

Join Date: Apr 2015

Location: near Charlotte NC

Posts: 4,681

Thanks: 1,443

Thanked 4,356 Times in 2,041 Posts

|

How about a picture of your wildcat 357/44 ?

__________________

03man(Don Voigt); Luger student and collector. Looking for DWM side plate: 69 ; Dreyse 1907 pistol K.S. Gendarmerie |

|

|

|

|

|

#9 |

|

Lifer

Lifetime Forum Patron Join Date: Feb 2009

Location: ...on the 'ol Erie Canal...

Posts: 8,208

Thanks: 1,425

Thanked 4,474 Times in 2,343 Posts

|

It's in the first post.

If you think this thread is boring, you should read some of my 3 & 4 page threads...

__________________

I like my coffee the way I like my women... ...Cold and bitter...

Last edited by sheepherder; 08-05-2018 at 12:44 PM. |

|

|

|

|

|

#10 |

|

User

Join Date: Apr 2015

Location: near Charlotte NC

Posts: 4,681

Thanks: 1,443

Thanked 4,356 Times in 2,041 Posts

|

Sorry,

I only went back as far as "yesterday"; amazing how the old threads get resurrected and then bite me in the derriere' .

__________________

03man(Don Voigt); Luger student and collector. Looking for DWM side plate: 69 ; Dreyse 1907 pistol K.S. Gendarmerie |

|

|

|

|

|

#11 |

|

User

Join Date: Jun 2002

Posts: 339

Thanks: 81

Thanked 359 Times in 198 Posts

|

The 357 Bain & Davis is like an old friend. It has been around a long time. I suspect that the B&D shop in California still will rechamber a N frame cylinder. Of course, Thompson Contenders were done in the day as well.

I too used a Smith Wesson 27, with a extra cylinder off ebay. I only have a lathe, so I used a poor man's version of an English bell chuck to center the chamber to the reamer/tailstock. I used a test indicator to zero the chambers. More work than your jig, but one uses what one has or can make. I can only dream of a nice mill and attachments. My S&W 27 in B&D version is a pinto, blue cylinder in a nickeled revolver, like yours a 8 3/8". Been pondering doing the 3 1/2" spare 27 revolver, but times change I guess, never done it yet. I believe the B&D or the 357/44mag wildcat versions will equal the newer, longer 357 maximum without the longer cylinder of say the V40 Dan Wesson. The V40 is a nice revolver, but really large one might say. I saw a picture once of a Dan Wesson revolver in 7mm-08 if my memory still serves some, a prototype only. Thanks for reviving the wildcat versions, made my day.........

|

|

|

|

|

|

#12 |

|

Lifer

Lifetime Forum Patron Join Date: Feb 2009

Location: ...on the 'ol Erie Canal...

Posts: 8,208

Thanks: 1,425

Thanked 4,474 Times in 2,343 Posts

|

For those two of you out there wondering what the 44/357 B&D looks like here is a pic of one...

The site I got this from says the longer taper was because B&D thought there would be problems with 'setback' so they elongated the neck-to-body transition... I've been reloading since the mid '70's and have never heard of 'setback'...I may very well know it by another term, but 'setback' is a new term to me...

__________________

I like my coffee the way I like my women... ...Cold and bitter...

|

|

|

|

|

|

#13 |

|

User

Join Date: Jun 2002

Posts: 339

Thanks: 81

Thanked 359 Times in 198 Posts

|

Thinking back, I believe I remember two versions of the 357 B&D. I think the basic difference was in the shoulder angle. One was much sharper than the other later one?

I have the gentle sloped version reamer. Bought off PTG's clearance rack. Not experienced any setback in my conversion so far; ie no locking up of the cylinder. Have lost some cases on fireforming, but relearned what heat is for in that process(annealing), solved that and a proper load. My S&W 53 in 22Jet will lock up the cylinder with a middle load and an oily chamber. Locks up the cylinder dead tight. So now, I have learned to lighten up some on the load and clean the cylinder's chambers with a oil removing solvent before shooting. always heard that the lockup in the jet was due to its long sloping shoulder. Not heard that with the 22 superjets though with the more conventional shape/shoulder in a revolver. The 224 Harvey Kay-Chuk does well in a K frame as well. Looking for a K frame to mount the K22 barrel and cylinder on, have the old Harvey reamer now; but no gumption due to our heat here. even considered the 22 Long Snapper in a K frame but no reamer yet. Just fun stuff.......... |

|

|

|

|

|

#14 | |

|

Lifer

Lifetime Forum Patron Join Date: Feb 2009

Location: ...on the 'ol Erie Canal...

Posts: 8,208

Thanks: 1,425

Thanked 4,474 Times in 2,343 Posts

|

Quote:

I never experienced 'setback' with my loads, and I don't recall Jim saying anything about his hot loads binding. Looking at my reloading notebook, I see that I used 13.0grs of Blue Dot with a 158gr JSP bullet. That was the 'sweet spot' for that bullet & powder in that barrel. Speer's Reloading Manual #10 shows that to also be the recommended max for that bullet/powder for the .357 Magnum. My notes don't show any mention of flat primers and I don't recall any. I know Jim's hot loads did, but I don't remember what we loaded his to. His model 29 had the 6" barrel; mine had the 8 3/8" barrel. They both shot very nicely, low recoil, minimal flash, seemingly flat shooting. I do recall that Winchester used a harder alloy brass that sometimes cracked when forming. The articles mention that annealing may be required. I found that Remington brass was much more ductile and did not need annealing. Looking through my old boxes of fired brass (not re-used) I see 13 'Frontier' cases. I don't recall those or where I got them. They look good. When I was forming the 357AMP cases, I found that 7.62mm military cartridges had a thicker case wall than .308" commercial cases. I've seen references that this is to minimize deformation when feeding in machine guns. For the Auto mag, I had to inside neck ream the military brass after forming because the wall was too thick. Then size it again. Too much work. I stuck to commercial brass. That was not a problem with the 357/44 for the revolver, as that used .44 Magnum brass necked down. But I stuck with Remington (or anything other than Winchester) for my 357/44 wildcat revolver cartridges.

__________________

I like my coffee the way I like my women... ...Cold and bitter...

|

|

|

|

|

|

| Tags |

| blivet |

| Thread Tools | |

| Display Modes | |

|

|