upload photo | donate | calendar

|

my profile |

register |

faq |

search upload photo | donate | calendar |

|

|

|

|

#1 |

|

Lifer

Lifetime Forum Patron Join Date: Feb 2009

Location: ...on the 'ol Erie Canal...

Posts: 8,208

Thanks: 1,425

Thanked 4,474 Times in 2,343 Posts

|

Re-barreling an M1896 Mauser

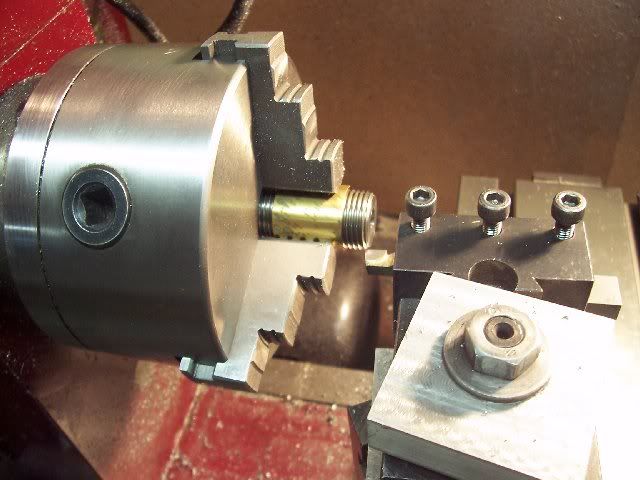

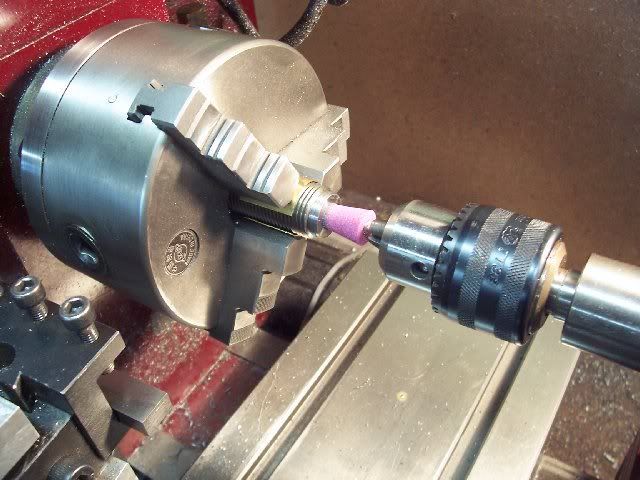

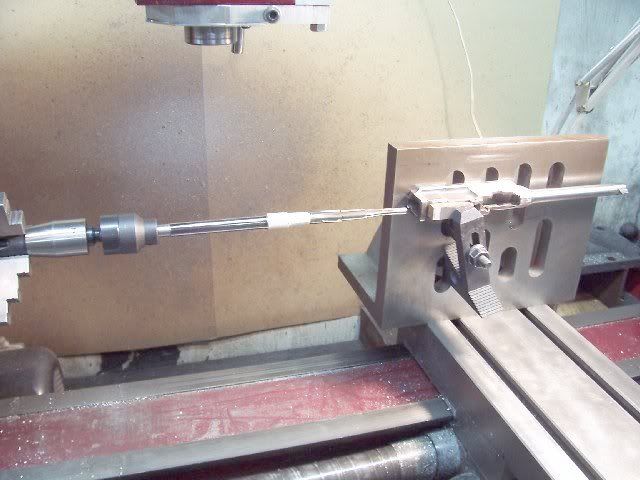

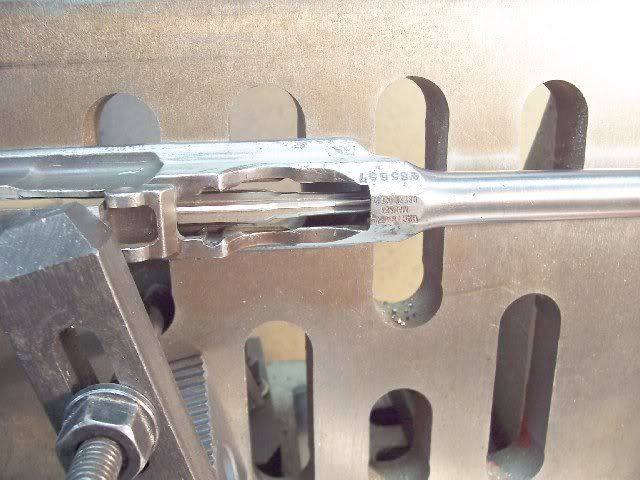

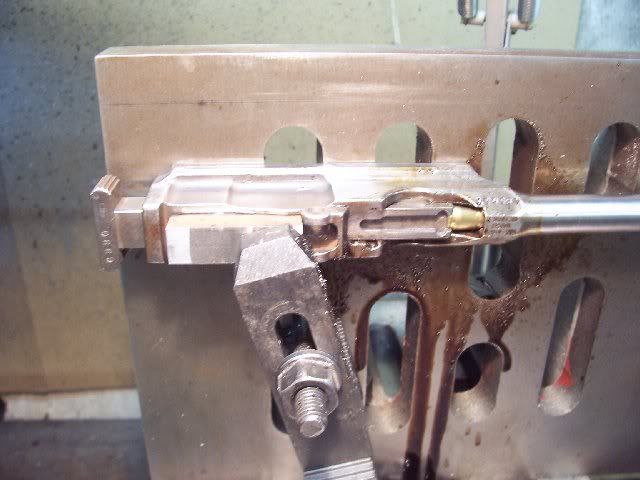

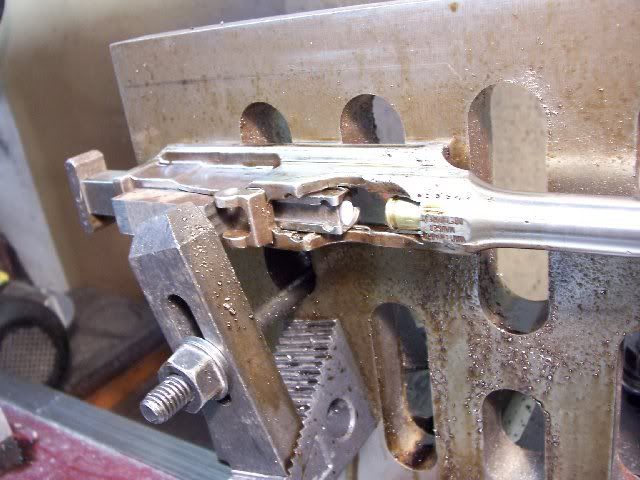

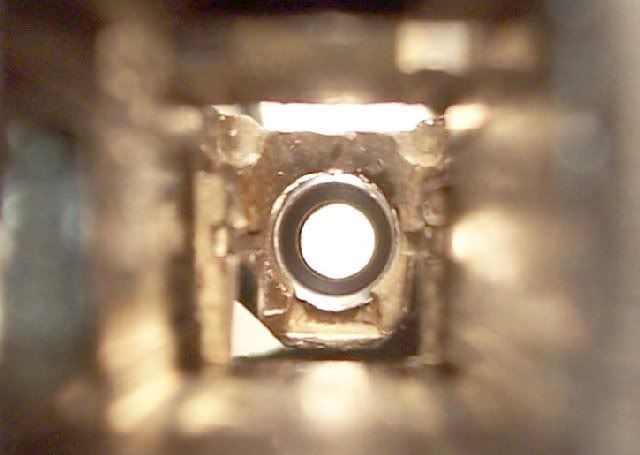

(Part two) Reaming the C96 barrel for a .256 bottleneck cartridge (This part presupposes that you have already installed a .256 caliber barrel blank on your Broomhandle). I'll be forming a wildcat cartridge out of .223 Rem unprimed brass, using shortened RCBS .256 Win Mag dies to make a .256 caliber bottleneck cartridge with the same OAL as the 30 Mauser cartridge.. First, we have to make the cartridge. I used a set of .256 Win Mag dies, shortened .185". I used a carbide cutter, low speed, and low feed. Shown is a finished brass cartridge, the dies before shortening, and a loaded cartridge with 60 gr soft nose bullet.  Cutting down the die; removing three threads as OEM RCBS die set...   Chamfering the base of the die with a 'fine' grit pyramid stone...  The finished shortened dies, and the shortening steps in the .223 Rem cartridges we're forming with them...  Now that I have a cartridge, I can ream out the barrel. I'm going to do it a bit backwards from my usual practice, with the reamer/extension/floating reamer holder held in the chuck and the barrel extension clamped to an angle plate. Plate is squared and extension leveled and centered to the reamer/chuck center. Reamer shown in position. Solid pilot Clymer .256 Win Mag straight flute chamber finishing reamer.   Starting the cuts...1/32" at a time, using high-Sulphur content cutting oil; squirt oil in, back out, blow off chips, repeat...   Taking a rough measurement, using stripped bolt and finished/formed unprimed dud cartridge...  Cutting some more...  Now I'm down to .050" from zero headspace...Lots of oil and chips...  Down to zero headspace. Now I run the reamer in an additional .004"...  A box of headspace dots, punched out of plastic shim stock...  The .004" dot on the bolt face. It's a blue dot; the flash makes it look white. I don't have any white dots...  And with the .004" dot in place, I have no movement. Reaming is done. Barrel is headspaced. Some pics of the finished chamber...    Overall view...  And a pic of the old/long .256 barrel stub, showing how much supported tube is threaded into the extension...  The new chamber still needs to have the extractor notch cut, and the feedramp cut & smoothed. I did a similar long-barrel/re-barrel in .256 caliber some years ago...I really liked it, but finding a shoulder stock the long-barreled Mauser will fit into has been unsuccessful...

__________________

I like my coffee the way I like my women... ...Cold and bitter...

Last edited by sheepherder; 09-08-2014 at 07:05 PM. |

|

|

|

| The following 7 members says Thank You to sheepherder for your post: |

|

| Tags |

| blivet |

| Thread Tools | |

| Display Modes | |

|

|