upload photo | donate | calendar

|

my profile |

register |

faq |

search upload photo | donate | calendar |

|

|

|

|

#1 |

|

User

Join Date: May 2006

Location: Minnesota

Posts: 25

Thanks: 0

Thanked 0 Times in 0 Posts

|

What is the proper way to seperate a toggle? Thanks

|

|

|

|

|

|

#2 |

|

Moderator

2010 LugerForum Patron Join Date: Jun 2002

Location: Santa Teresa New Mexico just outside of the West Texas town of El Paso

Posts: 7,051

Thanks: 1,121

Thanked 5,287 Times in 1,728 Posts

|

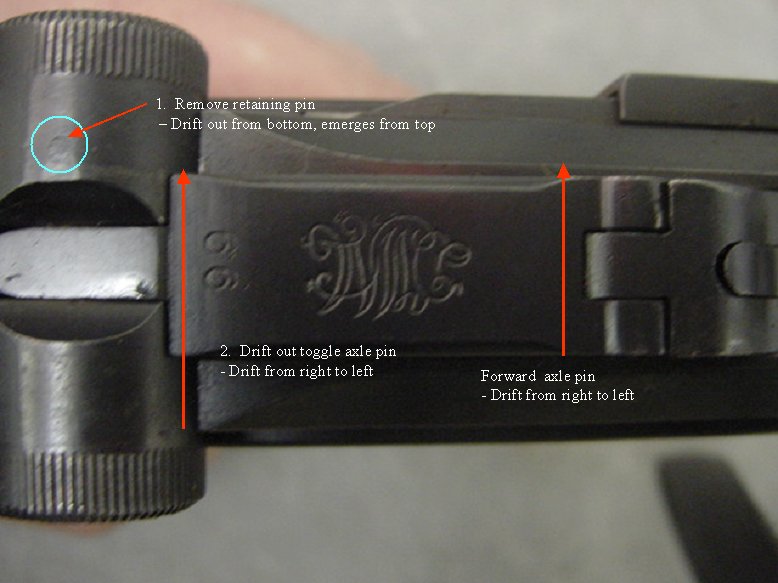

Is this what you are asking? Use the proper size punches and make sure all pins have been well soaked with oil to help overcome any that are frozen with rust. Last but not least, if there is not a problem that requires toggle disassembly, don't mess with it. If you damage it, I refuse to accept any resposibility.

__________________

If it's made after 1918...it's a reproduction |

|

|

|

|

|

#3 |

|

User

Join Date: Sep 2005

Location: east tn

Posts: 526

Thanks: 5

Thanked 12 Times in 5 Posts

|

Ron

What program are you using to do all the trick stuff over you photography? That is a great explanation on toggle disassembly. clint

__________________

Men Accustomed unto thier arms and their liberties will never endure the yoke. James Harrington 1776 |

|

|

|

|

|

#4 |

|

Moderator

2010 LugerForum Patron Join Date: Jun 2002

Location: Santa Teresa New Mexico just outside of the West Texas town of El Paso

Posts: 7,051

Thanks: 1,121

Thanked 5,287 Times in 1,728 Posts

|

Clint,

It is a multi-step process. 1. I paste the .jpg image into PowerPoint 2. Add the circles, arrows and text 3. Group the image and overlays using the "Group" function in PowerPoint 4. Do and "Edit" and "Copy" of the grouped images 5. Paste the copy into Paint Shop Pro (or Adobe Photoshop) as a "new image" and save as a .jpg. I can also resize the image or adjust the color balance in Paint Shop. Using the "save as" function in PowerPoint and saving as a .jpg is an option but it saves the entire slide and not just the image you are working on.

__________________

If it's made after 1918...it's a reproduction |

|

|

|

|

|

#5 |

|

User

Join Date: Apr 2006

Location: SF Bay

Posts: 195

Thanks: 16

Thanked 9 Times in 4 Posts

|

Thanks Ron,

I've resisted the temptation to attempt the toggle axle disassembly. The wisdom of 'if it ain't broke, don't fix it' seems inescapable.(-emphasis added by Admin-JS I do not recommend disassembly of this part unless it requires disassembly for repair or refinishing...) Someday, though, I'm sure there will be the occasion to do so. Just happen to have a set of punches left by my brother. Hmmmmmm. Russell

__________________

|

|

|

|

|

|

#6 |

|

User

Join Date: May 2006

Location: Minnesota

Posts: 25

Thanks: 0

Thanked 0 Times in 0 Posts

|

What happens when a pin does not want to break free. I have hit it with good sized hammer and it seems to be marking the pin but it is not coming out. On removing a barrel I have heard that putting it in freezer will help. Any tricks or should I use a hydralic press? Thanks

|

|

|

|

|

|

#7 |

|

User

Join Date: Jun 2003

Location: Plano Texas

Posts: 58

Thanks: 1

Thanked 0 Times in 0 Posts

|

I recently had a simular problem where a screw had been blued into a weight. I found the solution to be, heat the part in the oven in "clean" untell it gets as hot as you can get it. Then squirt it with circuit cooler that you get at Radio Shack. Remember use common sense and wear glasses and leather gloves!

__________________

In God we trust, all others we monitor! |

|

|

|

|

|

#8 |

|

User

Join Date: Sep 2006

Location: American Citizen outside the USA (Austria)

Posts: 65

Thanks: 0

Thanked 1 Time in 1 Post

|

Normally, no hydaulic press or any "violence" needed to disassemble a toggle! With heat, risk is to modify quality of steel...

Sometimes, with old shooter, the front pin breaks and you need to change it. good diameter punch, soft surface to protect blueing, that's all you need. You shouldn't try to do something else.

__________________

Swiss Lugers, (.30): DWM 1900, 1906 2nd variation, W+F 1906-24, 1929 Privat, 1929 Military, 9 mm 1929 Military. WW1 DWM German Lugers (9mm): Lange Pistolen P08-14 1916 & 1917, P08 1913, P08-14 1917, Navy P1904 altered safety, Navy P04-1906 downward safety. WW 2 Mauser German Lugers (9mm): 42-1940, byf 41, byf 42 black widow. And some other things... |

|

|

|

|

|

#9 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,156

Thanks: 3,003

Thanked 2,309 Times in 1,098 Posts

|

WARNING!... WARNING! WILL ROBINSON!

Bad advice Craig...this is no weight we are talking about... this part handles the stress of breech closure and a very sharp recoil cycle by beating itself against the ramps of the frame... Do NOT ever put any stress exposed part of a firearm (like a barrel, receiver, frame or slide, or in this case, part of the toggle or breechblock) into an oven on the "clean" cycle... you take the serious risk that you will modify the heat treatment of the steel and create a dangerous condition while firing... The "clean" cycle is designed to raise an oven far above the cooking range of temperature so that any food residue in the oven is burned until it is just ash and can be wiped out with a sponge... the cleaning temperature varies from oven to oven and between manufacturers and could jeopardize the safety of your Luger...

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#10 |

|

User

Join Date: Sep 2006

Location: American Citizen outside the USA (Austria)

Posts: 65

Thanks: 0

Thanked 1 Time in 1 Post

|

Thanks, John, that was what I tried to explain...

Stress in not good for humans and lugers ;-)

__________________

Swiss Lugers, (.30): DWM 1900, 1906 2nd variation, W+F 1906-24, 1929 Privat, 1929 Military, 9 mm 1929 Military. WW1 DWM German Lugers (9mm): Lange Pistolen P08-14 1916 & 1917, P08 1913, P08-14 1917, Navy P1904 altered safety, Navy P04-1906 downward safety. WW 2 Mauser German Lugers (9mm): 42-1940, byf 41, byf 42 black widow. And some other things... |

|

|

|

|

|

#11 |

|

User

Join Date: Jun 2002

Location: NC - USA

Posts: 1,239

Thanks: 0

Thanked 19 Times in 7 Posts

|

". . . sure all pins have been well soaked with oil to help overcome any that are frozen with rust."

Ron - What kind of oil do you use? How long so you soak? I bought a spare rear toggle link, and the pin is impossible to remove, even with a hardened steel punch and a good hammer. Thanks, Luke

__________________

"Peace, if possible; truth, at any cost." . . . Martin Luther |

|

|

|

|

|

#12 |

|

Moderator

2010 LugerForum Patron Join Date: Jun 2002

Location: Santa Teresa New Mexico just outside of the West Texas town of El Paso

Posts: 7,051

Thanks: 1,121

Thanked 5,287 Times in 1,728 Posts

|

Luke,

A light penetrating oil like 3-in-1 can be used as a bath to soak the toggle, maybe for a couple of days. A bit of liquid wrench applied directly to the pin repeatedly may help but isn't good for a bath since it can discolor rust blue with prolonged exposure (of course if you are going to refinish the part, that doesn't matter). And sometimes the darned things just aren't coming out so it is off to the gunsmith to have them drilled out and replaced. Usually the rear toggle joint pin isn't that difficult...that is why it has a retaining pin in the first place. Perhaps there was a burr kicked up the last time the retaining pin was installed or removed and that is what is holding the hinge pin in place.

__________________

If it's made after 1918...it's a reproduction |

|

|

|

|

|

#13 |

|

User

Join Date: Jun 2002

Location: NC - USA

Posts: 1,239

Thanks: 0

Thanked 19 Times in 7 Posts

|

Hi Ron,

Thanks for the info. Actually, I should have stated that my problem is not the large rear toggle joint pin, but the small retaining pin. These little buggers can really fit tightly sometimes. Luke

__________________

"Peace, if possible; truth, at any cost." . . . Martin Luther |

|

|

|

|

|

|