upload photo | donate | calendar

|

my profile |

register |

faq |

search upload photo | donate | calendar |

|

|

#1 | ||

|

User

Join Date: Jun 2002

Location: Portland, Oregon

Posts: 3,908

Thanks: 0

Thanked 1,330 Times in 435 Posts

|

Thoughts on this have been rolling around in the back of my head for awhile. Recent discussion of a Finnish pistol brought them to the fore, so I went back and found the last discussion of the topic which referred to a patent; it can be found here http://forum.lugerforum.com/showthre...t=fluted+georg

I've un-buried the discussion with this new post, with a quote from the last post of the original thread: Quote:

" F22 Firing Pin Early pins had plain cylindrical heads. By 1934, however, grooves were added to prevent obstruction by excess grease and oil. Ironically, this had been patented by Georg Luger (for rifles) as early as 1893: see DRP 78,406 and 90,433." It is a common recommendation hereabouts that shooters should replace their plain firing pins with fluted ones to disperse the pressure of blown-back gases in the case of a pierced primer. Here is part of another post in the same discussion: Quote:

The question is, really, where do you effectively redirect the gas pressure in the event of a pierced primer? The firing pin/channel in a Luger breechblock is a closely-machined fit, and makes a reasonably effective gas seal, at least to impulse pressure. The only aperture in it is the groove cut for the sear. I checked my 1936 S/42; there are three flutes cut each at 90�° to the other in the striker; there is no flute cut in the quarter parallel to the sear. In addition, the flutes themselves end fully 10mm ahead of the sear cut in the breechblock. It is apparent that the sear groove will not relieve impulse gas pressure. Finnish armorers apparently devised an effective gas release solution. Finnish Lugers can be found with a small hole drilled into the bottom of the breechblock, right at the back end of the notch cut for the holdopen to catch. This hole is enters the firing pin channel within the cavity formed when the firing pin is back in its cocked position, where it would be forced in the event of a primer breach, and provides a vent in that eventuality. Luger production which supplied the Finns occurred before 1934. This is not to say that the flutes do not serve a very useful purpose; that purpose is the original pointed out in Georg Luger's patent. As noted before, the firing pin channel is a rather close fit, and grease and dirt can impede the effectiveness of the striker. Examination of a fluted firing pin after a few hundred rounds firing amply reveals the flutes' effectiveness in collecting grease and powder residue. This is perhaps another reason they would make poor gas pressure channels, as this blockage would impede gas flow. I humbly sugggest here that the practice of changing to fluted firing pin for the protection of the breechblock in case of a pierced primer is unnecessary and deceptive, as it cannot offer this protection. There is a good reason to change a firing pin for shooting, and oddly enough, a fluted firing pin is a good choice. Classic Lugers are nearer the end of their use life cycle than the beginning. In a small survey of parts which commonly break in use http://forum.lugerforum.com/showthre...n+parts+survey it is demonstrated that firing pins are in jeopardy. In order to protect a matching-numbered firing pin from breaking (thereby reducing the value of the gun), it is worthwhile to replace it for that activity. The value of a fluted firing pin in this circumstance is that they are relatively newer (from 1934), and should be less prone themselves to breakage. --Dwight |

||

|

|

|

|

|

#2 |

|

Patron

LugerForum Patron Join Date: Jun 2002

Location: POB 398 St.Charles,MO. 63302

Posts: 5,089

Thanks: 6

Thanked 737 Times in 484 Posts

|

Dwight, I would be more willing to accept your "logic" on this subject, if you had actually run some test and had some experimental data to report. I agree that venting excess gas thru a hole in the bottom of the breech block is probably an improvement in a M23 DWM, but this was only done because a PROBLEM EXISTED. I believe that Mauser's use a the vented firing pin, was probably equally effective. TH

|

|

|

|

|

|

#3 |

|

Lifer

Lifetime Forum Patron Join Date: Jun 2002

Location: The Capital of the Free World

Posts: 10,156

Thanks: 3,003

Thanked 2,309 Times in 1,098 Posts

|

I would like to offer my thoughts on both your comments, having had a smattering of mechanical engineering manufacturing experience, and more than few years doing work on shooting lugers...

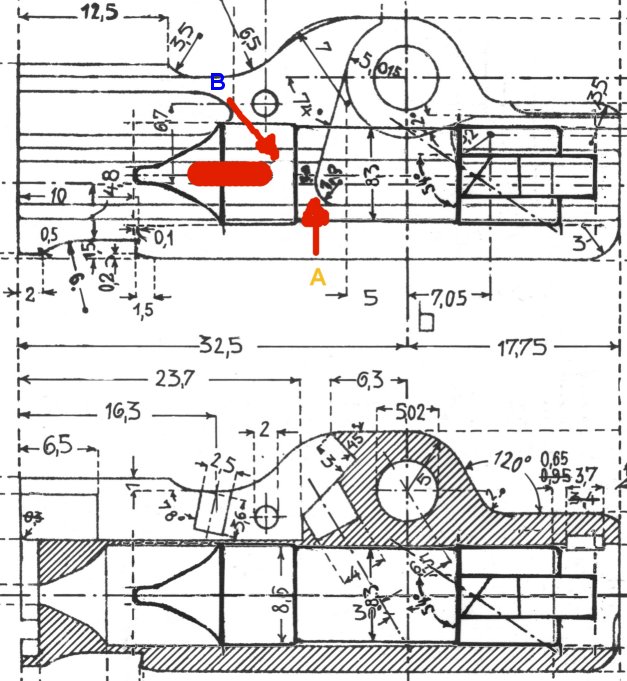

While Dwight has performed no physical live fire testing (not only potentially dangerous to the operator, but chances the destruction of some parts), I think his analysis has a great deal of merit. I have always accepted without question the "pierced primer" theory for the flutes, but have always recognized their value in providing clearance in a dirty environment for the firing pin to do it's job adequately in the close fitting channel. Performing detailed cleaning of war-veteran Lugers has in my experience always produced a good deal of what can only be called CRUD in the forward area of the firing pin channel in the breechblock. I don't know how much crud it would take to prevent the firing pin from providing adequate impact to set off primers, but I am sure that the flutes make the productive service of the firing pin longer between cleanings... Having peaked my interest in the engineering aspect, I did a short study of the Luger blueprints, and have concluded that Dwight is correct in his premise that the flutes, even if on the same plane as the sear groove, fall short of reaching the groove to release the pressure that may be present due to a pierced primer. The front edge of the sear groove in this blueprint "what if" is indicated by the arrow marked "A"... One of the flutes is simulated in RED, and as you can see on my working print, actually falls about 5mm from reaching the sear groove with the firing pin in the rear most position... For this reason, I have to concur with Dwight, that the flutes would offer no improvement in the release of pierced primer gas escape, and in fact, the area of the firing pin between point A and point B would act as a piston ring, and the entire firing pin would act as a piston... most likely breaking off the retaining pin boss and damaging the breechblock in the process. If the sear groove were elongated to provide access to the flute, I think the release of primer gas might just blow the sear and sear spring right off the gun... and in the process, mess with the structural integrity of the breechblock. The Finnish solution is an excellent one, that mimics the solution we (USA) used on the 1903 A3 Springfield, by drilling a release hole in both the bolt, extractor and receiver ring... to vent an accidental primer puncture. The obvious likely result of gas escaping through the bottom hole in the M23 Luger breechblock might be that the magazine would be blown out by the force of the escaping gas, but that damage to the overall pistol would be unlikely... I would consider the addition of a fluted firing pin and the drilling of a gas release hole in the breechblock area described to be a logical improvement over the original design if performed on SHOOTING class Lugers... Not collectors items. I hope this diagram has been helpful in this very interesting discussion. and now a word from my profit center  TODAY is the last day of my 20 percent discount sale on my Luger Blueprint CD... details are in the FOR SALE forum... TODAY is the last day of my 20 percent discount sale on my Luger Blueprint CD... details are in the FOR SALE forum...

__________________

regards, -John S "...We hold these truths to be self-evident that ALL men are created EQUAL and are endowed by their Creator with certain UNALIENABLE rights, and among these are life, LIBERTY, and the pursuit of happiness..." |

|

|

|

|

|

#4 | |

|

User

Join Date: Jun 2002

Location: Portland, Oregon

Posts: 3,908

Thanks: 0

Thanked 1,330 Times in 435 Posts

|

Quote:

I agree that this was entirely in the realm of thought experiment and logic. A practical test did occur to me after I wrote it. It should be possible to chamber a primerless cartridge case in a complete upper section; attach a pressure hose to the muzzle; connect it to a pressure chamber; and relese a measured pressure pulse of air into the barrel; to see how much pressure it takes to move the firing pin to its fully retracted position under spring pressure. Repeat this test with both firing pins in a clean and normally lubricated breechblock. If it takes -much- more pressure to move the fluted striker then the flutes have an effect; if the pressure is about the same, the flutes provide no advantage. For a control, this test should be done with both an Imperial and WWII Mauser P-08. This test should actually be fairly easy to arrange. This is not something I can follow up on at the moment, but I am intrigued. As far as the problem existing, I noted that experience here on the Forum has shown that a pierced primer can damage the breechblock. I wonder how much this has to do with the age of these pistols and the change in the metallurgy of the steel over time. Its interesting that the Finns recognized the problem and needed a solution. I have to wonder if their problem was environment-related? Would the severe cold-soak weather conditions cause primers or breechblock steel to be more brittle? --Dwight |

|

|

|

|

|

|

#5 |

|

User

Join Date: Jun 2002

Location: Iowa

Posts: 768

Thanks: 0

Thanked 19 Times in 11 Posts

|

I am wondering if a small hole in the bottom of the breech block would relieve pressure fast enough to prevent damage to the breech block/striker assemby.

|

|

|

|

|

|

#6 |

|

Moderator

Lifetime LugerForum Patron Join Date: Oct 2002

Location: Europe

Posts: 5,053

Thanks: 1,036

Thanked 3,991 Times in 1,205 Posts

|

There is another fail safe already built into every luger. The lug on the bottom of the chamber prevents the receiver from moving further backwards than planned, thus reducing chances of damaged breech blocks by unwanted pressure build-ups.

|

|

|

|

|

|

#7 |

|

User

Join Date: Jun 2002

Location: Portland, Oregon

Posts: 3,908

Thanks: 0

Thanked 1,330 Times in 435 Posts

|

Gerben,

The reports on these Forums of breechblock damage from pierced primers are of blown-out firing pin retainers and fractures of the surrounding metal; and blown out top-front edge of the breechblock along with the extractor. --Dwight |

|

|

|

| The following member says Thank You to Dwight Gruber for your post: |

|

|

|