It's a slow day...

Cleaning out the trash in my basement and storage shed, I found this jig which I had made and used for re-chambering S&W N frame .357 magnum cylinders to a wildcat .357/.44 cartridge. I thought I'd do a quick & dirty write-up of it, as it turned out quite successful.

Back in the 80's, a friend and partner of mine was interested in magnum pistols. Jim had a .45 Lar Grizzly Magnum auto; I had a .357 AutoMag and a .44 Ruger Blackhawk. On a lark, I ran a .44 magnum case through the .357 AutoMag reloading/sizing die. It looked 'cool', so I showed it to Jim. Jim had a blued 6" bbl .357 magnum S&W N frame and was enthusiastic, and I caught his enthusiasm. A co-worker of Jim's had a nickel S&W N frame .357 magnum, and he was only asking $325 for it...I bought it. Jim dug up a spare .357 magnum cylinder for his N frame from somewhere, and I started designing.

First thing was to get a reamer. Back then, the Clymer family owned the Clymer reamer business and would grind special/custom reamers for customers. Supply them with two dummy cartridges and a set of dimensions and they would grind a custom reamer for you. I did this and got my custom .357/.44 magnum reamer.

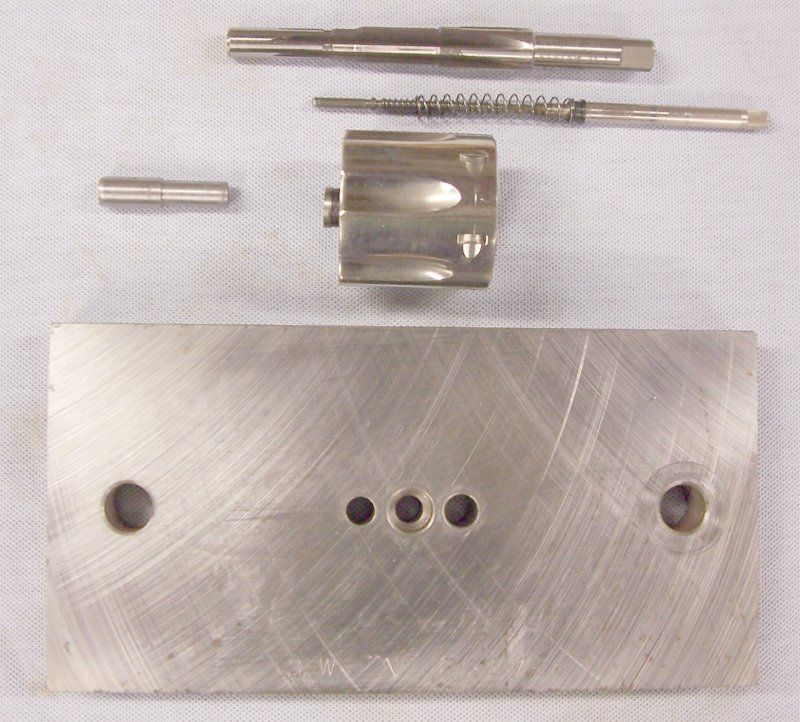

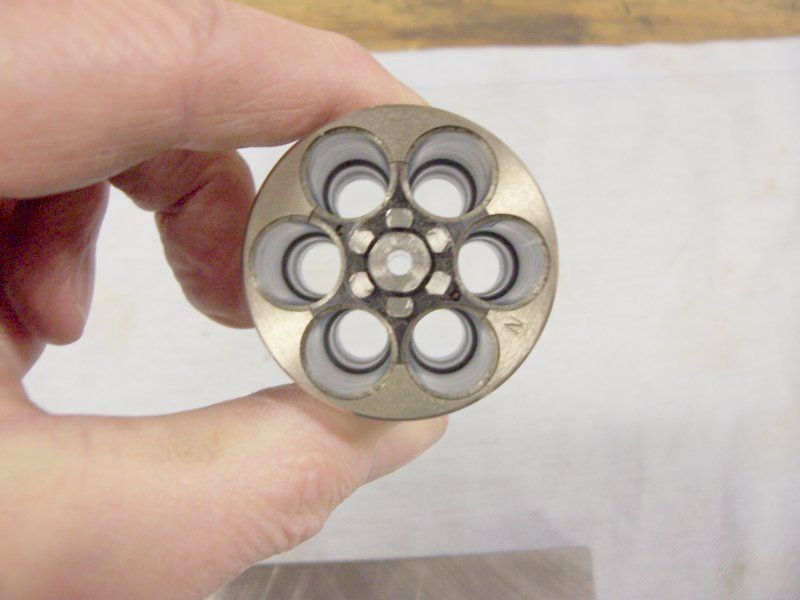

I had a Bridgeport 2J mill back then, and made up this jig to hold the cylinder. The 3/4" steel plate is surface ground and bored to accept the cylinder spigot and a special pin to locate the cylinder. Basically, you bolted the jig to the mill table, aligned the hole in the right side to the mill quill, clamped the cylinder to the jig/table, and reamed the cylinder, with extractor left in place. Headspace was left the same as S&W had headspaced the .357 cartridge. Keep rotating the cylylinder until all 6 chambers had been reamed.

Cylinder timing was unaffected. The pin was an exact fit in the front of the cylinder and precisely centered the chamber for reaming.

The N frame was also offered in .44 magnum as well as .357 (in fact, it was designed for .44 mag first and then offered in .357 by popular demand) so there was no question of the .357 cylinder being too thin or weak - it was the same .44 mag cylinder only bored for .357 - it was designed for .44 magnum pressures.

I did my S&W and Jim's and IIRC at least one other...CRS and missing/non-existant receipts complicate my memories...Jim died young & suddenly some years ago, and his daughter took care of his estate. I don't know what happened to his cylinder. I still have mine, as well as a second .357 mag cylinder and a 4" barrel.

The cartridges shot flat and fast, as you might expect, with a very satisfying hollow sounding noise. I loaded my cartridges conservatively, but Jim liked his hot. I had the only .357 AutoMag dies, so I loaded his. He'd shoot progressively hotter loads until the primer started to flatten...Then he'd say it was just right...And we'd run off a couple hundred.

This wildcat is similar to the .357 Bain & Davis but without the long taper. This cartridge gives more support for the bullet than the B&D. And I already had the AutoMag dies.

Wildcatting was fun back then. We'd show up at the range, unload our stuff and start banging away. Me with the AutoMag and S&W, Jim with his Lar Grizzly and S&W. After about 15 or 20 shots, we'd look around, and there would be people hanging out of the clubhouse windows & doors to watch the fireballs...