Milling the front sight 'blade'.

25. Finished front sight fitted to barrel.

26. Squaring/shortening muzzle protrusion.

27. Milling sides of 'blade'; milling top to 1º angle.

28. Milling radius on front of 'blade'.

Had to break off barrel work again, to make a spanner for that front sight.

A. Boring the hole in a block of 5/8" x 1 1/2" 6061 aluminum.

B. Milling a clearance slot for the 'blade'.

Next will be finishing operations on the front sight.

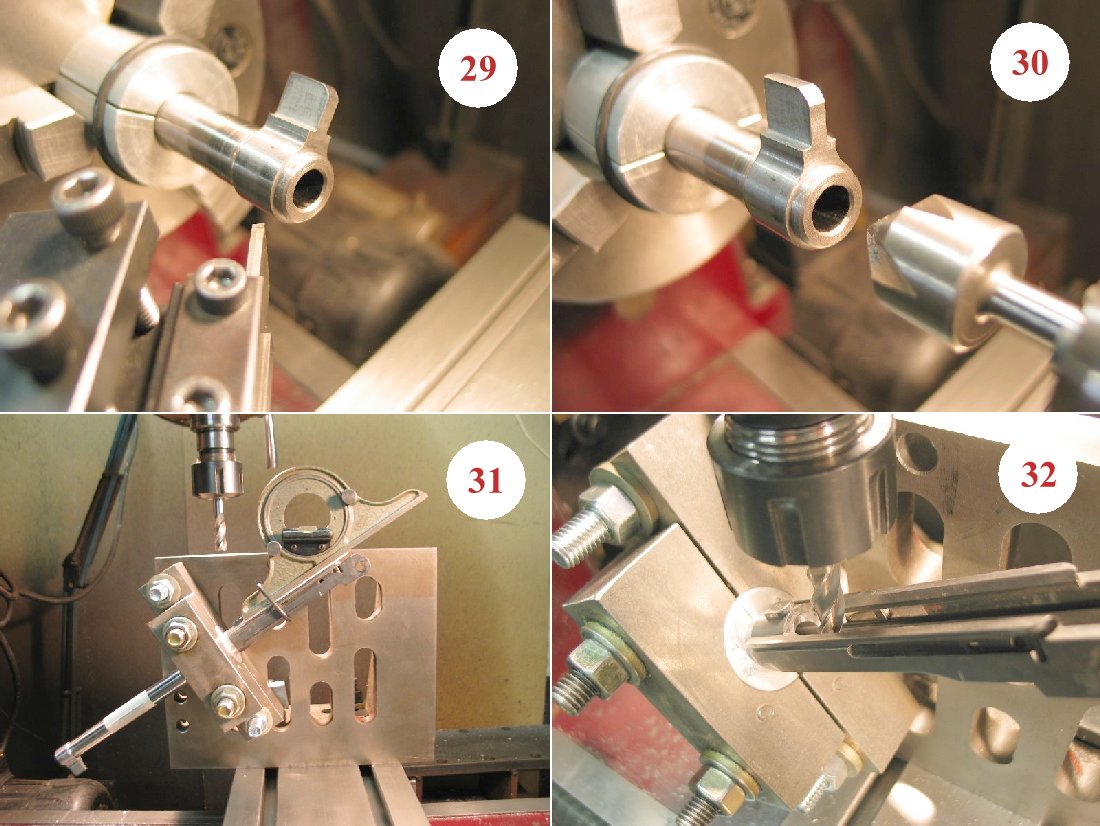

29. Beveling the muzzle.

30. Crowning the muzzle bore.

31. Setup to mill the chamber ramp.

32. Milling the ramp, using a 10mm end mill.

Finishing operations at the breech end of the barrel.

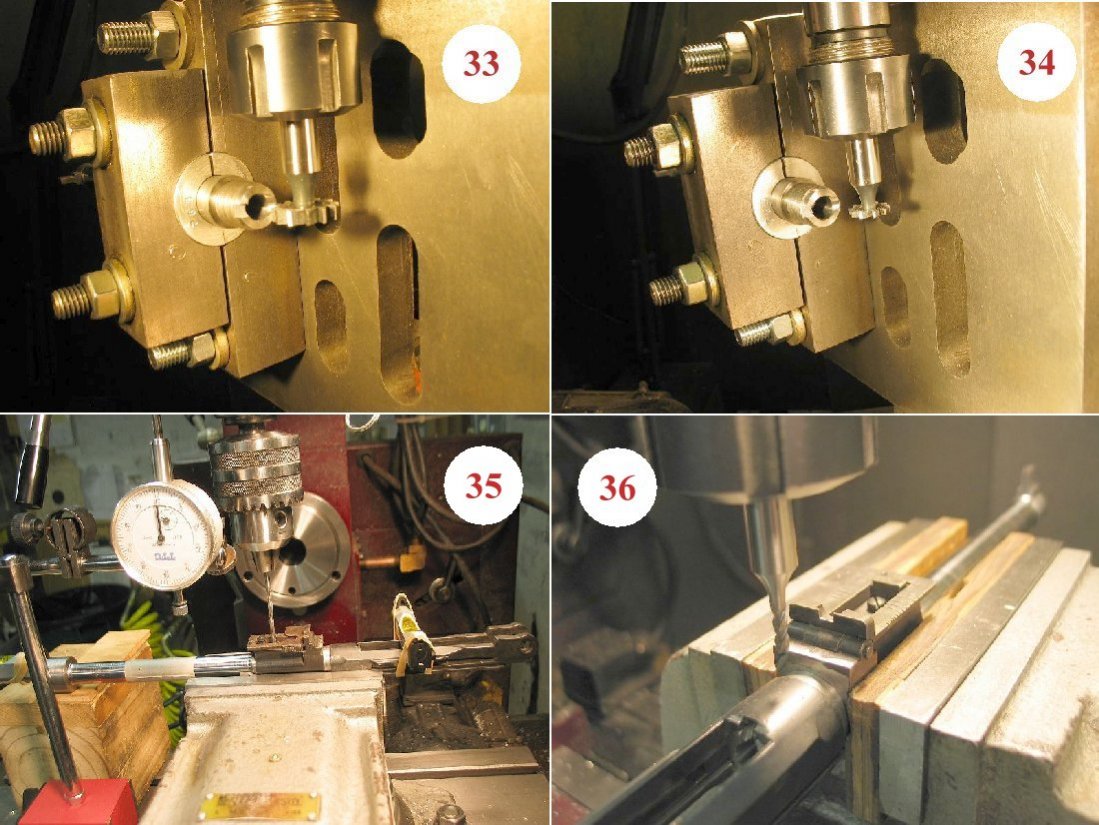

33 & 34. Cutting the extractor notch with Woodruff keyway cutters.

35. Drill & tap the rear sight base retaining screw (#6 x 48tpi).

36. Setup to cut a Patridge notch in the rear sight to replace the 'V' notch: finished cut.

Getting near the end...

At this point, my machine work on this 'fantasy barrel' is done. It needs to be sent out for final finishing and bluing, and when it comes back I'll assemble it and check functioning.