I would like to offer my thoughts on both your comments, having had a smattering of mechanical engineering manufacturing experience, and more than few years doing work on shooting lugers...

While Dwight has performed no physical live fire testing (not only potentially dangerous to the operator, but chances the destruction of some parts), I think his analysis has a great deal of merit.

I have always accepted without question the "pierced primer" theory for the flutes, but have always recognized their value in providing clearance in a dirty environment for the firing pin to do it's job adequately in the close fitting channel. Performing detailed cleaning of war-veteran Lugers has in my experience always produced a good deal of what can only be called CRUD in the forward area of the firing pin channel in the breechblock. I don't know how much crud it would take to prevent the firing pin from providing adequate impact to set off primers, but I am sure that the flutes make the productive service of the firing pin longer between cleanings...

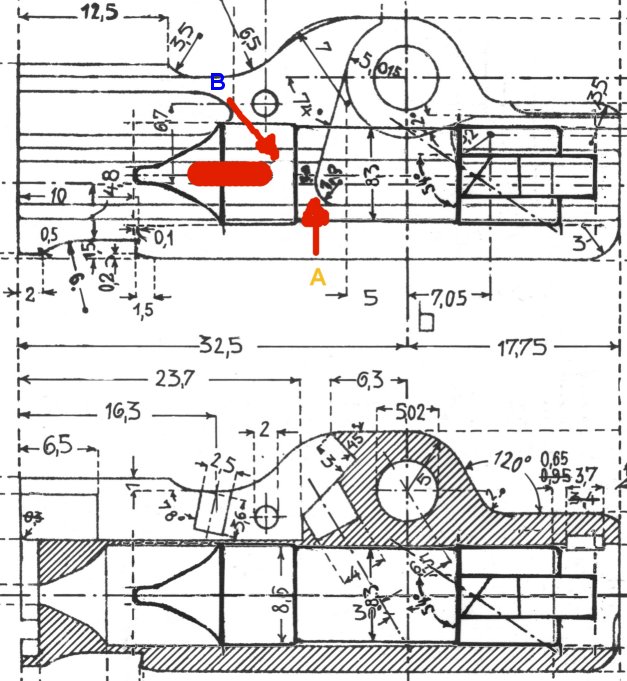

Having peaked my interest in the engineering aspect, I did a short study of the Luger blueprints, and have concluded that Dwight is correct in his premise that the flutes, even if on the same plane as the sear groove, fall short of reaching the groove to release the pressure that may be present due to a pierced primer. The front edge of the sear groove in this blueprint "what if" is indicated by the arrow marked "A"... One of the flutes is simulated in RED, and as you can see on my working print, actually falls about 5mm from reaching the sear groove with the firing pin in the rear most position...

For this reason, I have to concur with Dwight, that the flutes would offer no improvement in the release of pierced primer gas escape, and in fact, the area of the firing pin between point A and point B would act as a piston ring, and the entire firing pin would act as a piston... most likely breaking off the retaining pin boss and damaging the breechblock in the process.

If the sear groove were elongated to provide access to the flute, I think the release of primer gas might just blow the sear and sear spring right off the gun... and in the process, mess with the structural integrity of the breechblock.

The Finnish solution is an excellent one, that mimics the solution we (USA) used on the 1903 A3 Springfield, by drilling a release hole in both the bolt, extractor and receiver ring... to vent an accidental primer puncture.

The obvious likely result of gas escaping through the bottom hole in the M23 Luger breechblock might be that the magazine would be blown out by the force of the escaping gas, but that damage to the overall pistol would be unlikely...

I would consider the addition of a fluted firing pin and the drilling of a gas release hole in the breechblock area described to be a logical improvement over the original design if performed on SHOOTING class Lugers... Not collectors items.

I hope this diagram has been helpful in this very interesting discussion.

and now a word from my profit center  TODAY is the last day of my 20 percent discount sale on my Luger Blueprint CD... details are in the FOR SALE forum...

TODAY is the last day of my 20 percent discount sale on my Luger Blueprint CD... details are in the FOR SALE forum...