While doing another project, I remembered I needed a magazine for this fantasy barreled Luger. I visited Greg Cote's web site and ordered two more blued Muc-Gar Luger magazines. Unfortunately, they now come with plastic followers and bases. I don't like that look, so I emailed Gerry at

G.T. Specialties. Gerry used to make some beautiful polished aluminum bases. He no longer makes them, which is a loss for us all, but he said he had an East German cast aluminum base, so I ordered one of those. They're undrilled blanks, as-cast, slightly oversized, and the casting seam is uneven. But they're 'good enough' for my amateur projects. Gerry once told me that he had various (and many) jigs for producing his excellent magazines and components, which produced uniform and correct pieces. I've only converted about a dozen Mec-Gar magazines so far, and I'm a firm opponent of 'production lines', so I only have the minimum of mandrels/jigs/fixtures to convert Mec-Gar magazines to all-metal items.

Here's what I do. Not as good as Gerry, but my customers (all one of me!) haven't complained.

Here's a blow-by-blow account of my base/follower modifications.

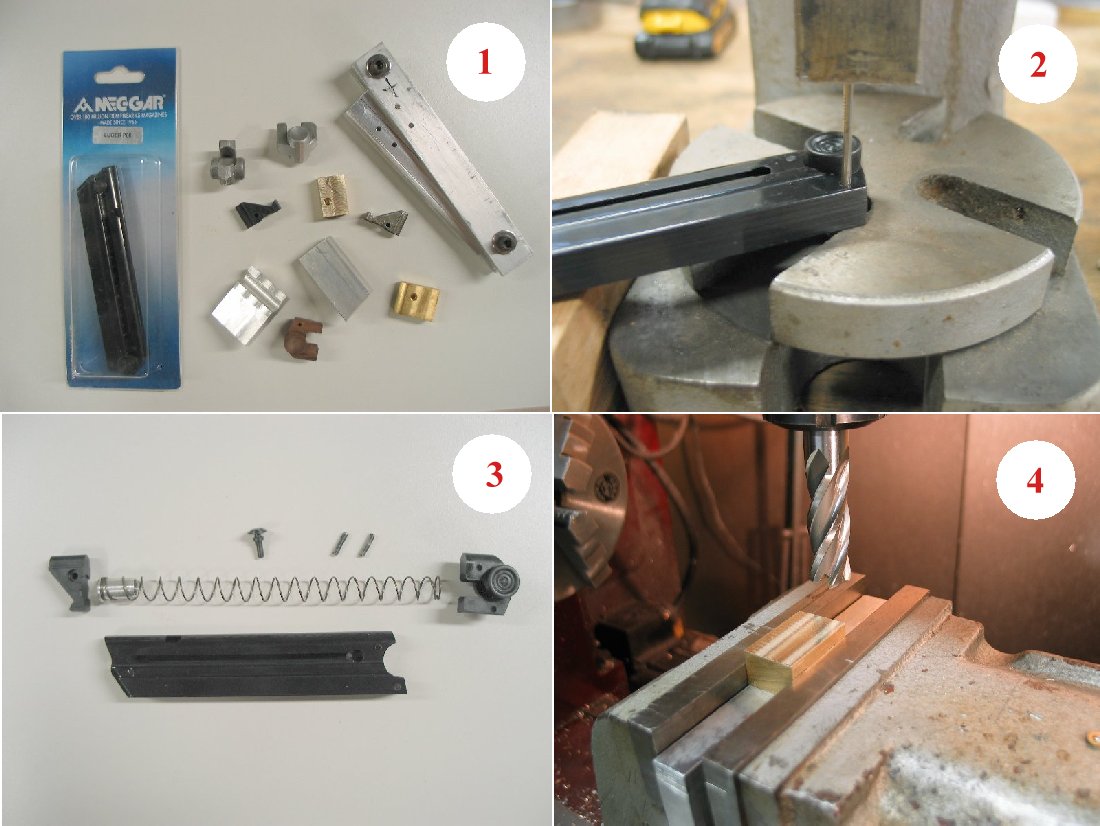

1. Some of the stock, parts, and mandrels I use.

2. Drifting out the base pins. Gerry has fantastic fixtures for doing this, but for my low-volume (two), my 1-ton press and some ground down drill rod blanks work just fine.

3. The disassembled Mec-Gar P08 magazine. Removing the button is always an annoyance, as the hole on the opposite side does not line up with the button hole. Argh!!!

This seems to be typical of original Luger magazines as well.

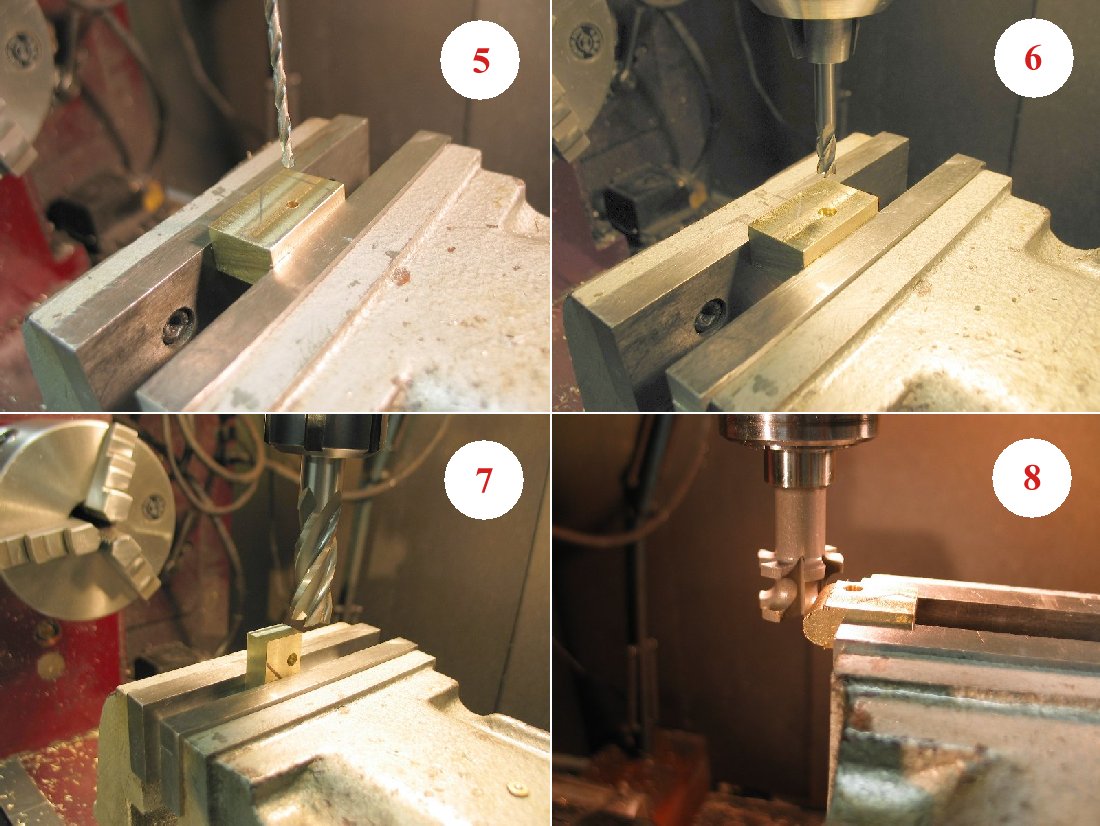

4. I take a piece of brass bar stock for the follower and mill it to the approximate dimensions of the Mec-Gar follower, which is not the same as a P08 follower.

5. I start with drilling the button hole as my datum point.

6. Relieving the button hole with a 5mm end mill.

7. Milling the front edge to spec.

8. Half-round milling the front edge with a special end mill.

I like brass. I especially like it for magazine followers as its lead content adds to its lubricity.

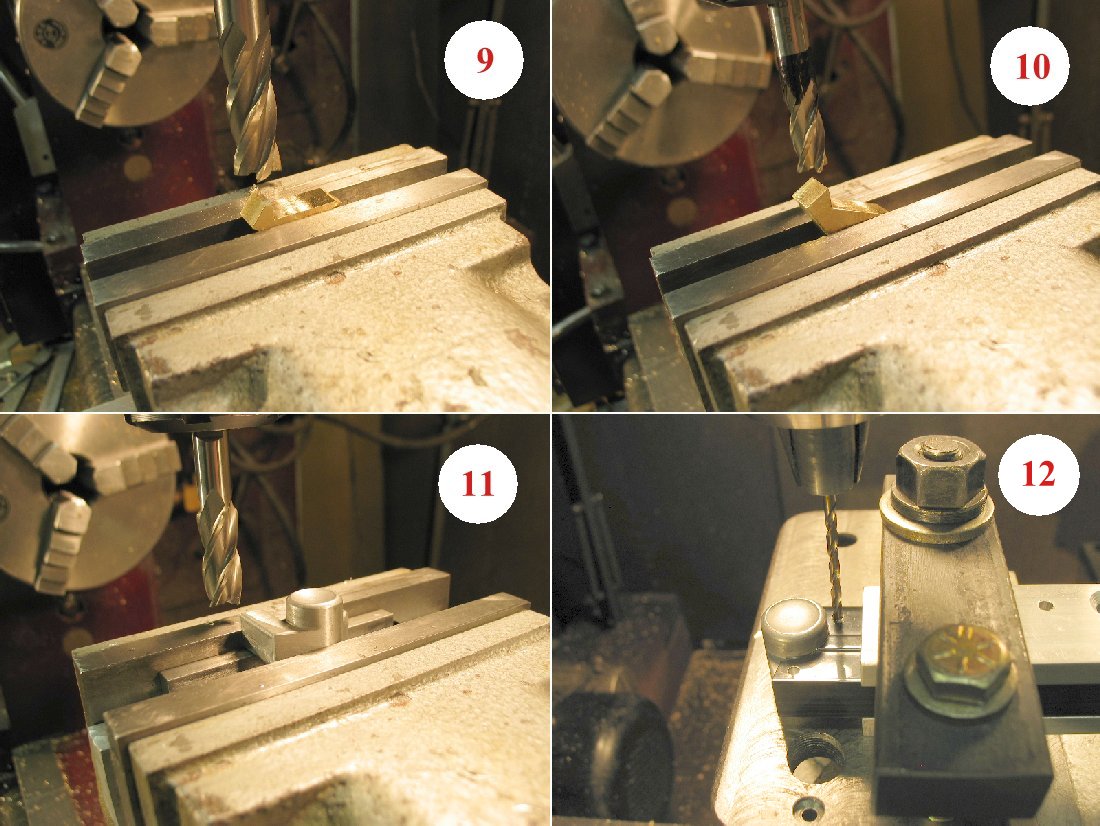

9. Milling the step in the top of the follower.

10. Milling the base of the step in the follower. I'll break all sharp edges but other than that, this follower is finished.

Now I need to pay some attention to the aluminum base.

11. The 'East German' magazine base blank is too thick, so I'm taking a skim cut off each side until it is a snug fit.

12. Drilling the base blank for the Mec-Gar pins.

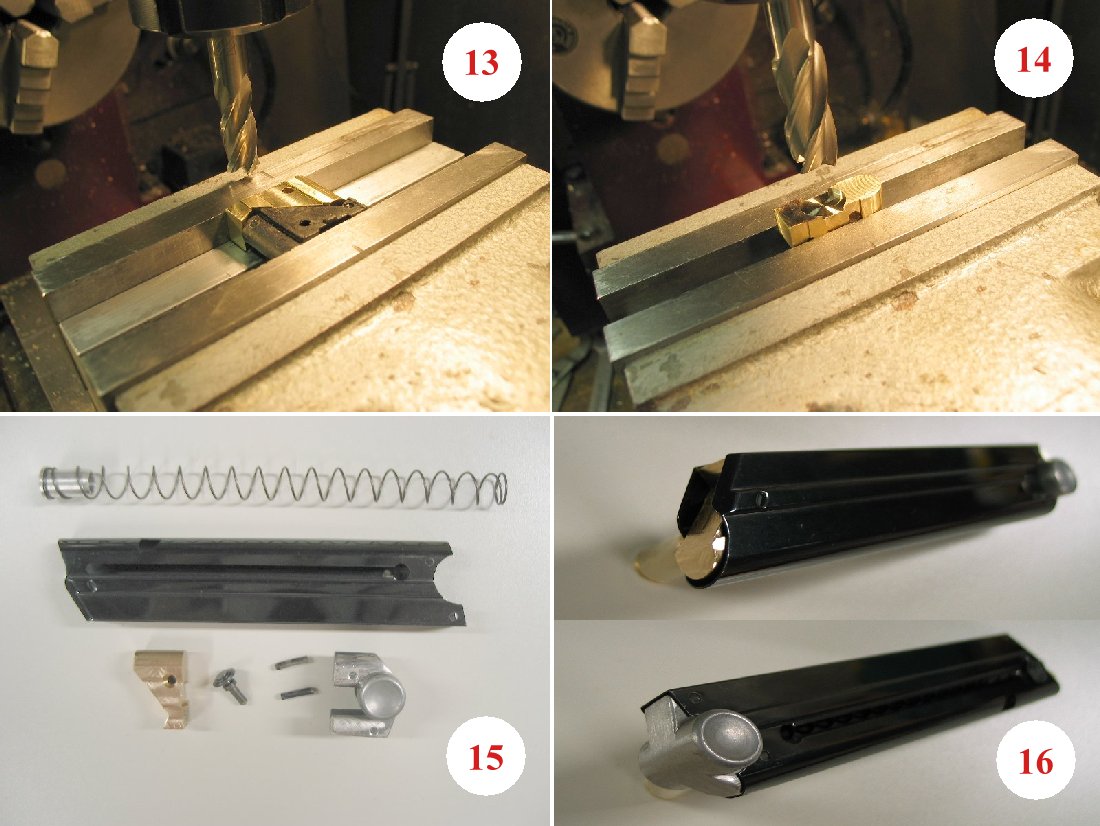

13. Milling reliefs on both sides.

14. Milling spring pocket in bottom.

15. Finished parts awaiting assembly.

16. Assembled magazine with brass follower and aluminum base.

Not as nice as G.T.'s work, I'm afraid. Adequate but not pretty.

Oh, well. It only has to work.

Pic of installed magazine. It locks in place and trips the hold-open. What more could you ask for???