Some years back, I bought a book by George Nonte called

Pistolsmithing. It is a compilation of many of his articles from various magazines. One comment was of particular interest, and concerned the M1896 Mauser.

I was intrigued by this, and decided to do a re-barrel of my own, on a shot-out C96 'Broomhandle' Mauser. I obtained a spare barrel extension from Gunbroker.com, and a 30 caliber rifled blank, and set out on my quest!

Re-barreling an M1896 Mauser

(Part One)

Re-barreling an M1896 Mauser

(Part One)

OK, this is a quick & dirty pictorial on re-barreling a C96. Not every step is shown; not every step makes sense. It's actually drawn from several re-barreling projects, including one long-barrel .256 caliber wildcat.

First I saw off the barrel. I part the receiver at the point where the M30 'Broomhandle' barrel has its 'step'. I've read that this was a popular way to re-barrel C96's 'back in the day', and this was where the old-time gunsmiths cut the barrel off.

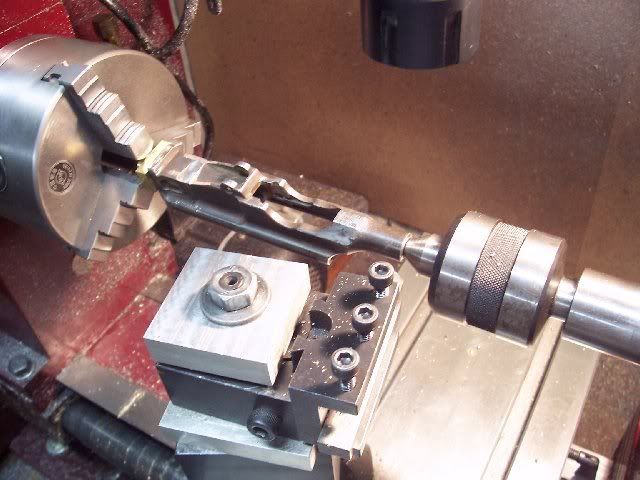

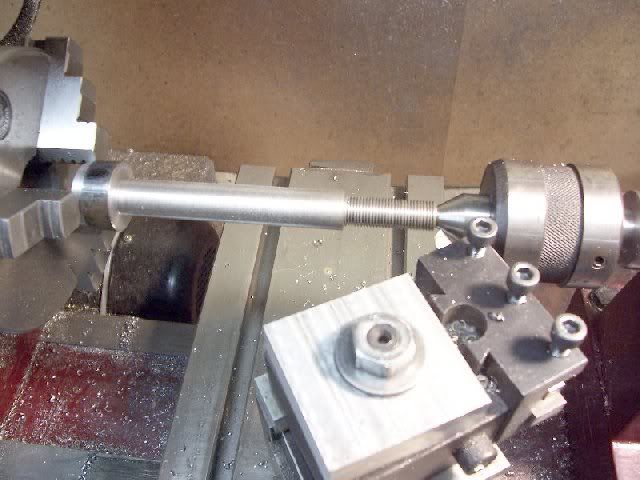

Now I face off the stub. Here I'm using a live center in the existing bore as my center, and a custom made receiver mandrel to center the rear of the receiver.

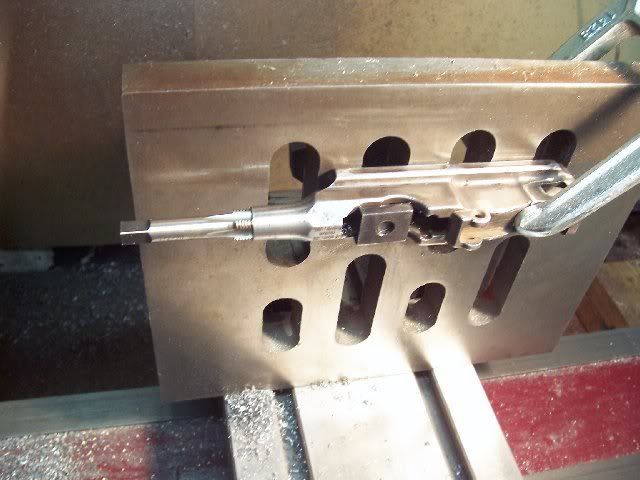

Custom turned mandrel in lathe chuck, mounted extension on angle block, leveled and squared to chuck...

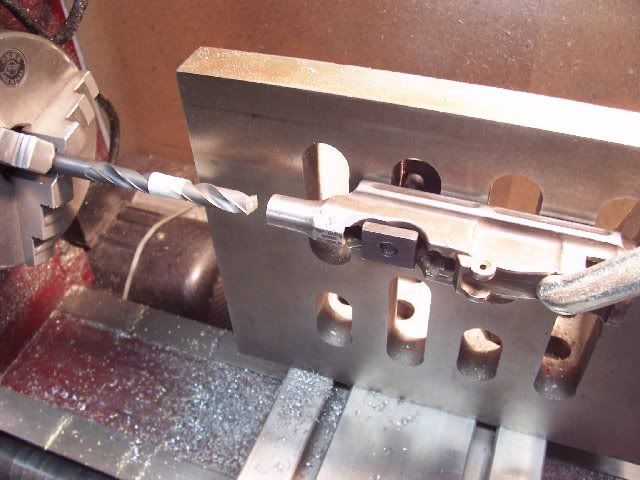

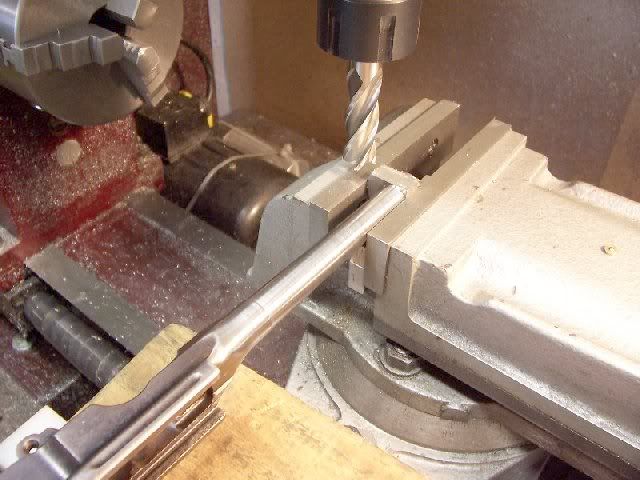

Drilling out the extension stub...

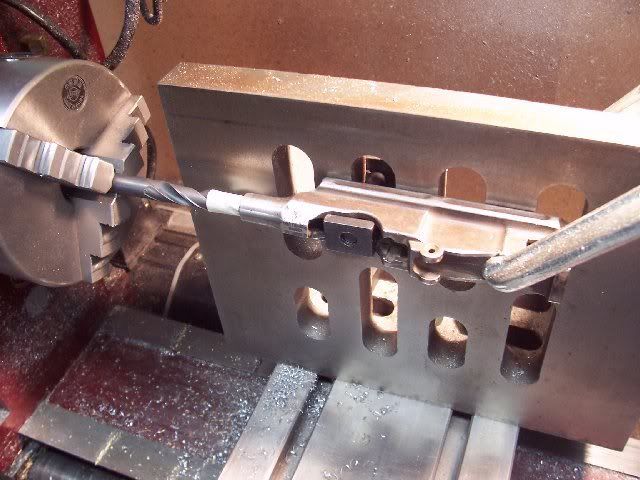

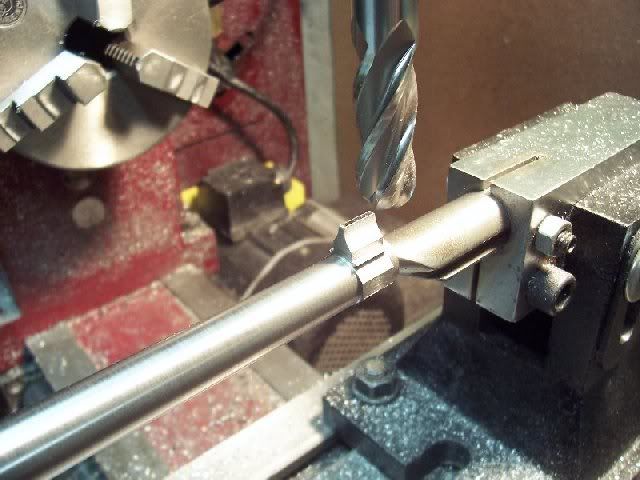

Tapping the stub. I turn the tap by hand; the chuck is just to steady the tap and keep it on center...

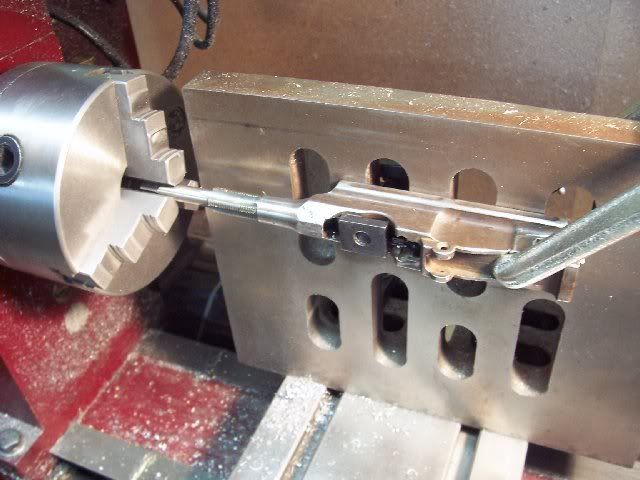

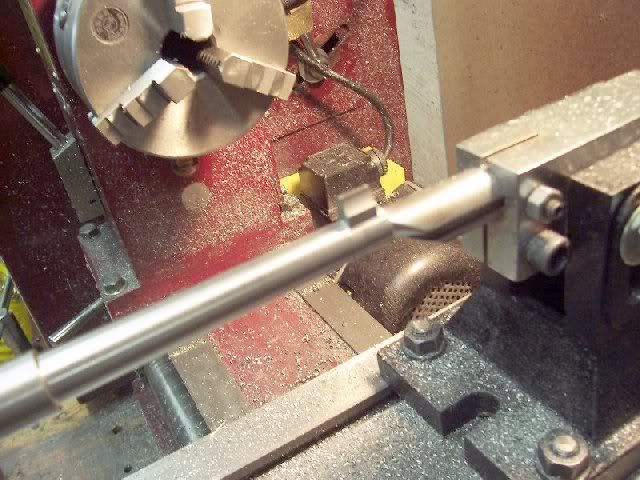

Receiver/extension stub tapped and ready for barrel...

Now we go to the barrel blank...

Sawed to length and turned to approximate diameter...

Chamber end threaded; snug fit on receiver. Front sight end left unfinished...

Barrel and receiver...

Front sight end being worked...

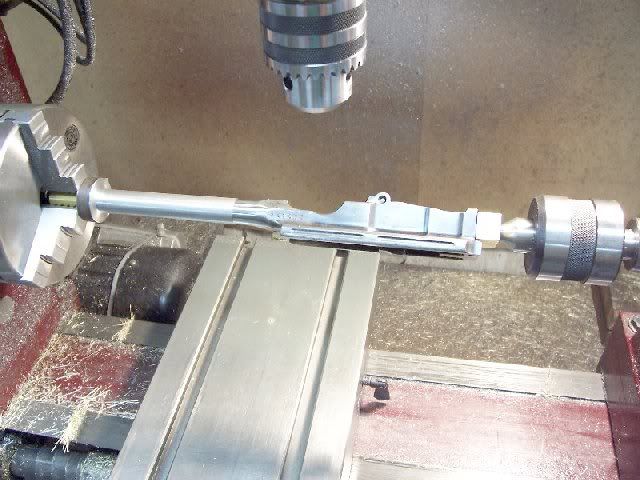

Barrel mounted and torqued; now being tapered. Jacobs chuck inadvertedly left in mill quill [D'OH!!!}...

Getting there...

Rough milling the sides & bottom of front sight. 4x4 & 2x4 blocks used as shims to steady unsupported receiver; otherwise, it would vibrate....

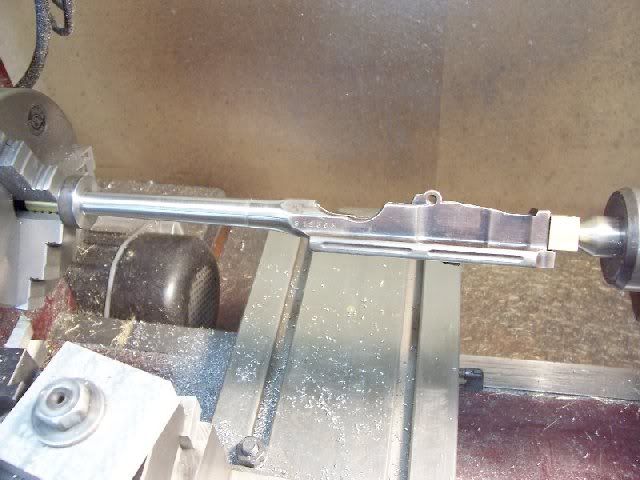

Barrel in rotary indexing head; cutting front sight blade. Threaded sleeve used to protect barrel threads.

Cutting the barrel/front sight sides & bottom; 4º at a time...

Nearly finished barrel & receiver/extension...

I'll ream the chamber in Part Two...